|

|

Biography

Wolfhard Zisser received the degree of Diplomingenieur in industrial engineering from the Technische Universität Wien in 2011. He joined the Institute for Microelectronics in November 2011, where he is currently working on his doctoral degree. His scientific interests include interconnects, electromigration, and molecular dynamics simulations.

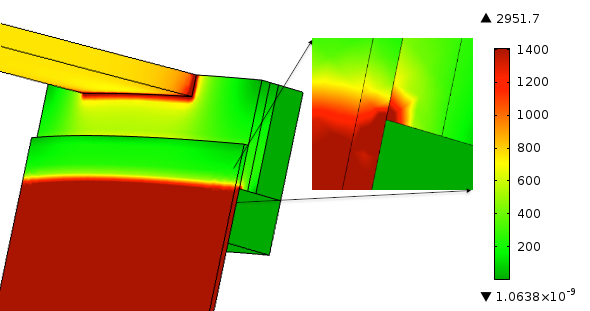

Analysis of Electromigration in TSVs

Three-dimensional (3D) integration is a promising approach for the development of devices with higher performance. In these devices the planar integration is extended in the third dimension by wafer stapling. As a result, the planar interconnect structures also have to be extended to vertical connecting components, like solder bumps and Through Silicon Vias (TSVs). Important issues for these new structures are the typical interconnect degradation processes, such as electromigration and stress migration. Degradation processes decrease the reliability of new interconnect structures and thereby of whole 3D integrated circuit.

Electromigration is the process of material transport due to the flow of electric current and the exchange of kinetic energy between the electrons and the ionized atoms of metals. This material flux builds up stress in the interconnects. After some threshold stress is reached, the nucleation of voids can occur at positions where the cohesion of the interconnecting metal and the surrounding material is weakened. As the flow of material continues, these voids can move and grow in time and thereby increase the resistance of interconnects, ultimately leading to failure.

TSV are components that accomplish the vertical interconnection inside the wafers. Two different types are used nowadays. The first type forms a metal filled cylinder reaching from one side to the other of the wafer, whereas the second forms a cylinder barrel. In these components tungsten and aluminum are the two metals that carry electrical current. Due to the complexity of the TSV geometry and material composition, Technology Computer Aided Design (TCAD) simulations are needed to determine the most probable locations of failure and degradation mechanisms leading to failure. These simulations are performed by means of the Finite Element Method (FEM). Simulations enable us to study different failure scenarios by varying the geometry and operating conditions. In such a way the possible reliability risks can be predicted.

Fig. 1: Current density (in kA) in a segment of the TSV.