|

|

Biography

Florian Rudolf, born in Austria 1984, studied technical mathematics at the Technische Universität Wien. 2012 he received the degree of Diplomingenieur and started working on his doctoral degree on the Institute for Microelectronics. His scientific interests are geometry, computer graphics, and programming.

Template-Based Mesh Generation and CAD-Based Mesh Healing for Semiconductor Device Simulation

Meshing is an important ingredient for numerical solutions of partial differential equations. An example in the area of microelectronics is the solution of the drift-diffusion system for semiconductor device simulation, where a finite volume method imposes high requirements on the quality of the generated meshes. The ViennaMesh meshing framework has proven to be a solid and flexible software framework for tackling meshing issues which occur in these types of simulations.

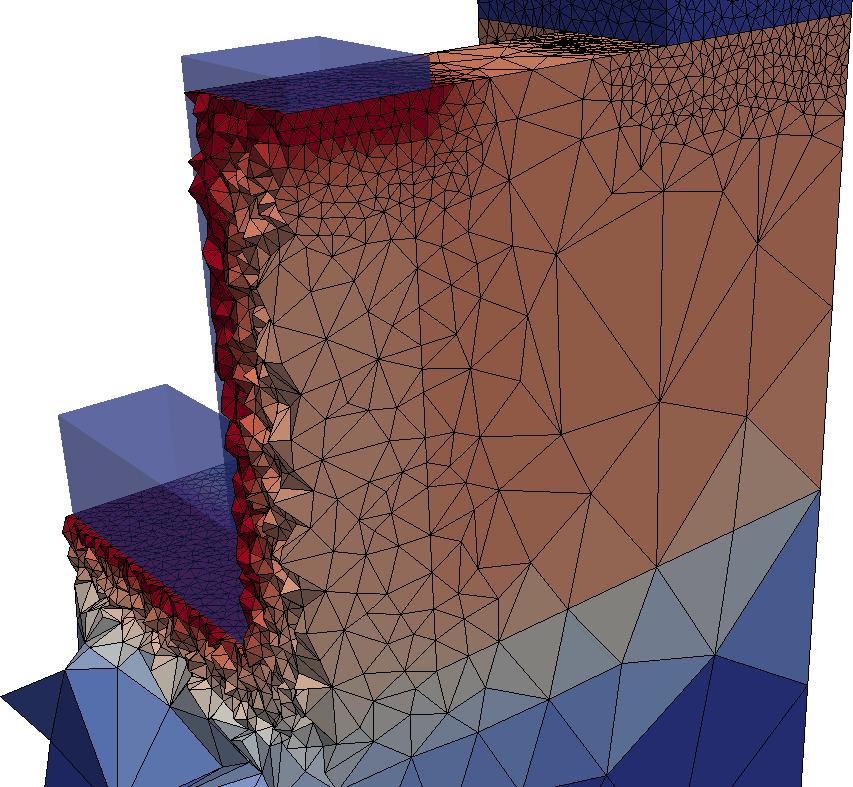

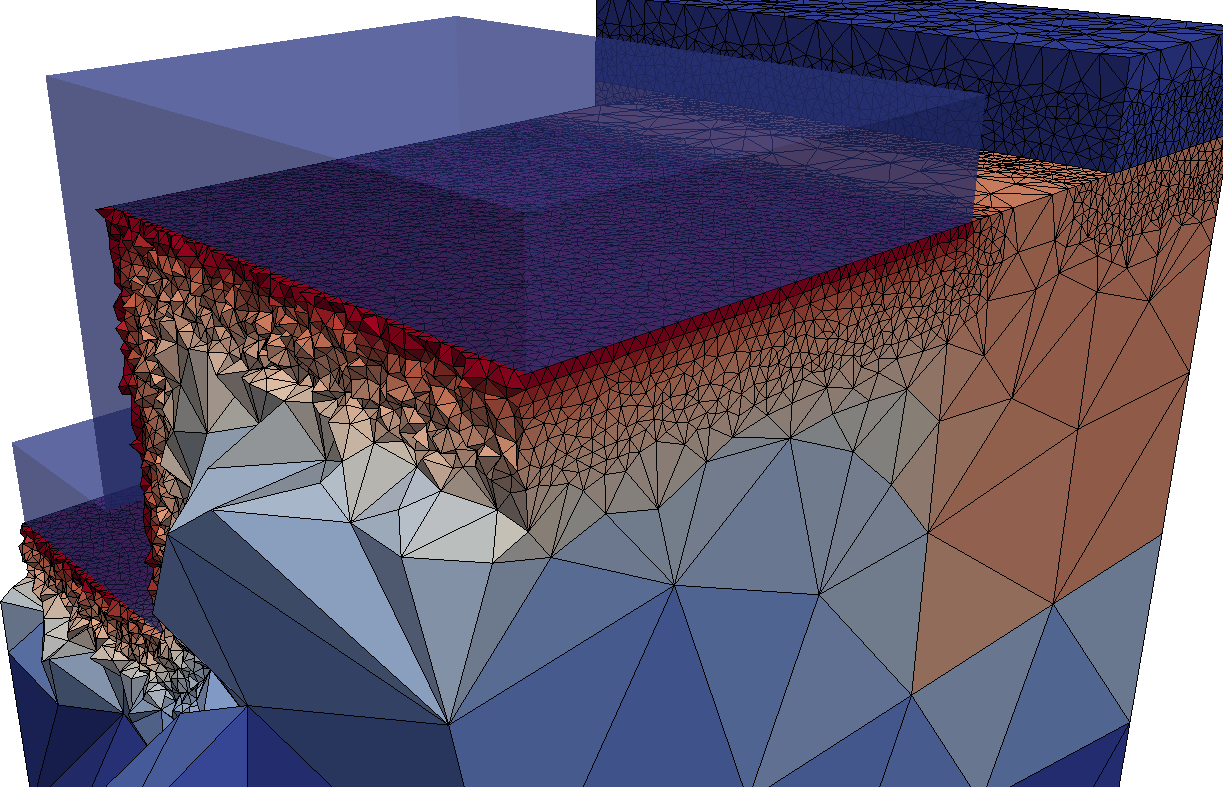

Although device geometries might be quite complex, in many cases only a few geometric parameters are of interest, such as the gate length, the gate width, and the oxide thickness in MOSFET devices. Nevertheless, changing a specific geometric feature generally affects other parts of the geometry. Thus, with classical geometry representations, like boundary representations, all parts of the geometry that are influenced by such a change have to be recreated manually. We developed a formalism which allows us to simplify the geometric description such that only a few parameters are needed to describe a whole family of devices. An implementation is made available to the public in ViennaMesh framework, which is able to generate geometries based on a geometry template and a set of input parameters representing geometric features. The geometry template mechanism enables easy and convenient mesh generation of different geometries of the same object to compare numerical simulation results or optimize geometric parameters. Fig. 1 and Fig. 2 visualize simulated meshes based on the same geometry template of a 3D FinFET device that was parametrized with a gate length of 18nm and 90nm, respectively.

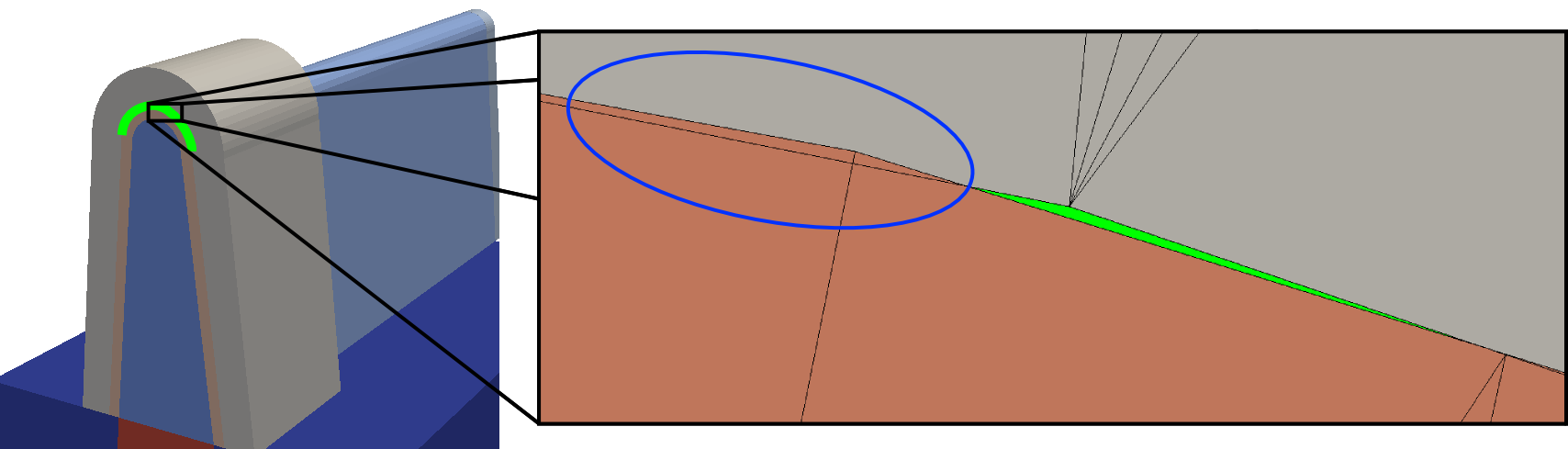

Often, device geometries in TCAD processes are generated using parametric solid modeling CAD tools. However, geometries generated with these tools often lack geometric properties, like being intersection-free, which are required for volumetric mesh generation as well as discretization methods. Fig. 3 shows an example of possible geometric errors (overlap, intersections and holes on region interfaces). Contributing to this problem is the fact that device geometries often have multiple regions used, e.g., for assigning different material parameters. Therefore, a healing process of the geometry is required, which detects and repairs errors. Most geometry and mesh healing algorithms originate in the field of computer graphics and therefore have to be adapted to meet the geometric requirements of a mesh suitable for TCAD simulation. Common errors in device meshes generated with CAD tools have been investigated and a mesh healing pipeline based on the multi-material marching cube algorithm has been developed to encounter these errors. The algorithms used by this pipeline have been implemented in open source meshing framework ViennaMesh.

Fig. 1: A sliced 3D FinFET device generated using a geometry template with 18nm gate length. The simulated electron concentration is visualized.

Fig. 2: A sliced 3D FinFET device generated using a geometry template with 90nm gate length. The simulated electron concentration is visualized.

Fig. 3: Hole (marked green) and intersection errors (marked blue) in a 3D bulk silicon trigate transistor due to different discretizations of neighboring regions. The green area on the left indicates the areas where these errors occur.