|

|

Biography

Vito Simonka was born in Murska Sobota, Slovenia, in 1991. He holds a bachelor's and master's degree in Physics from the University of Maribor, Slovenia. He joined the Institute for Microelectronics in August 2015 as a research assistent. His scientific interests include computational modeling for process TCAD, in particular SiC oxidation.

Three-Dimensional Directional-Dependent Silicon Carbide Oxidation

We investigate geometrical aspects of silicon carbide (SiC) and propose a directional-dependent interpolation method for computing oxidation growth rates for three-dimensional simulations. Additionally, we analyze the temperature dependence of SiC oxidation for different crystal directions. Our approach is an essential step towards highly accurate three-dimensional oxide growth simulations and extends oxidation models by incorporating crystal direction dependence into the modeling of the oxidation growth rate. We focus on the 4H-SiC and 6H-SiC polytypes as they have been recognized as the most promising materials for electronic high power, high frequency, and high temperature applications.

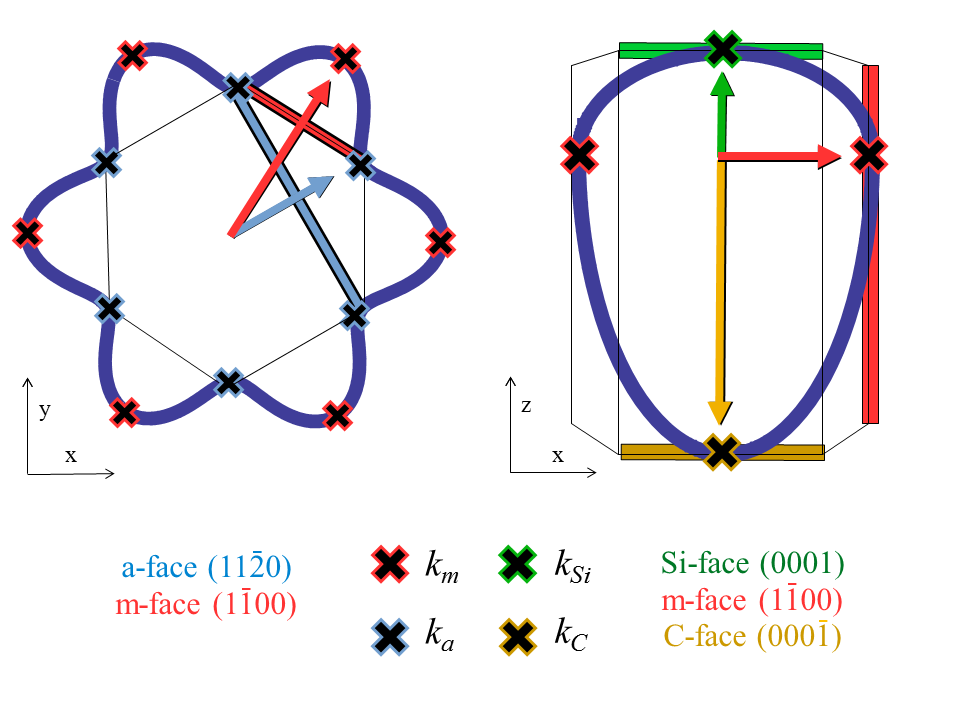

An interpolation method converts an arbitrary crystal direction into a growth rate of oxidation according to known growth rates (see Fig. 1). For fixed points of oxidation growth rate values we use the (0001), (10-10), (11-20), and (000-1) directions, which have been examined experimentally and correspond to the Si-, m-, a-, and C-plane, respectively. As the oxidation of SiC is strongly dependent on temperature, we use Arrhenius plots to analyze the effect of temperature on growth rates. This allows one to obtain fixed growth rate values for different oxidation temperatures directly.

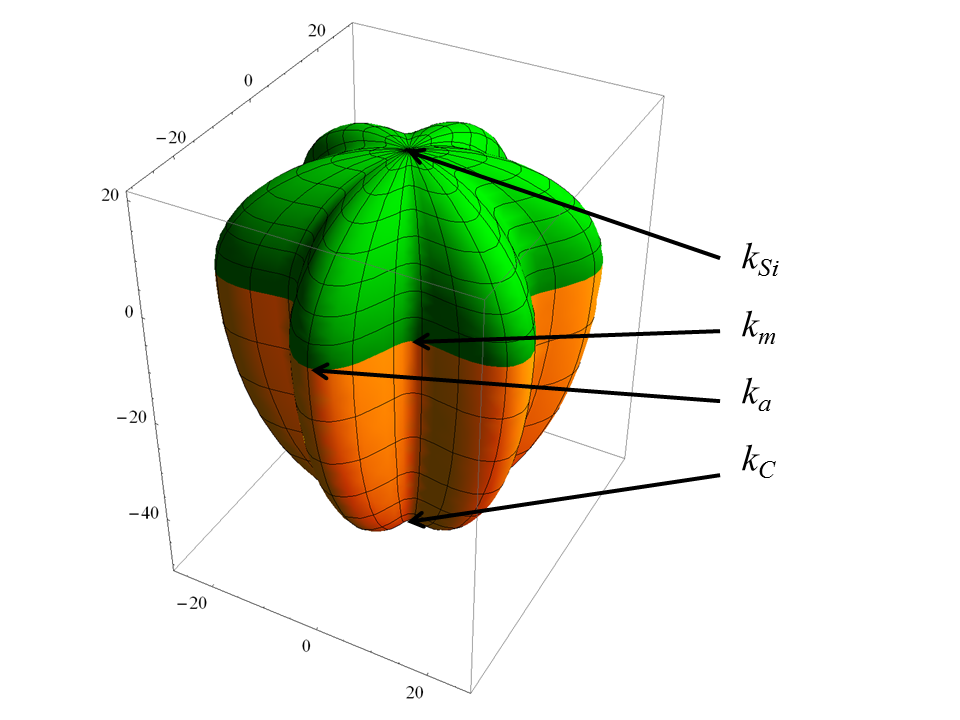

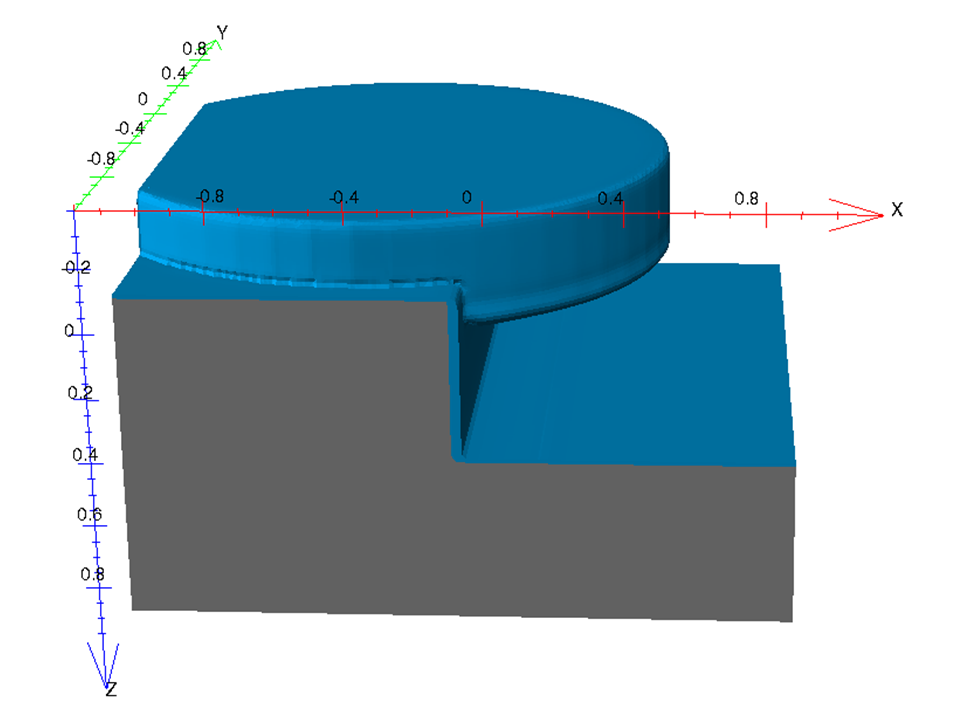

Fig. 2 shows the full three-dimensional SiC oxidation growth rate surface. The surface consists of a symmetric star shape in the x-y plane and a tangent-continuous union of two half-ellipses in the z-direction. Fig. 3 depicts SiC thermal oxidation simulations with SILVACO's Victory Process using the proposed interpolation method, together with Arrhenius plots and available oxidation models.

With the proposed interpolation method, we calculate the growth rate of oxidation in three-dimensional space (see Fig. 2), where the distance from the origin to the surface of the plot defines the value of the oxidation rate. These results are then used for three-dimensional simulations of thermal oxidation of an arbitrarily shaped SiC sample(see Fig. 3).

Fig. 1: Schematic illustration of the proposed interpolation method in the x-y (left) and x-z plane (right). The linear (black dashed) and non-linear (dark blue line) interpolations are calculated according to the four known growth rate values (black crosses) of Si- (green), m- (red), a- (blue), and C-face (orange square). Colored arrows represent crystal direction vectors, which point toward the corresponding faces. The length of the arrows is proportional to the oxidation growth rates.

Fig. 2: Three-dimensional parametric plot of 4H-SiC oxidation growth rates. An arbitrary direction growth rate is calculated according to the four known growth rates (k_{Si}, k_m, k_a, and k_C) shown with black arrows. The surface color shows the calculations for the positive (green) and negative (orange) z-direction.

Fig. 3: Three-dimensional simulation of SiC thermal oxidation with the process simulation framework Victory Process using our interpolation method. Simulations were performed for dry thermal oxidation of 4H-SiC (0001) Si-face (n-type, on-axis) at T = 1100 °C for 120 minutes. Gray areas are 4H-SiC and blue areas are SiO_2.