5.2.1 Carbon Fluorides for Silicon Dioxide Etching

When modeling the plasma etching of silicon dioxide, it is important to include microloading phenomena which cause tapered vertical walls on the

etched SiO profile [151]. The tapering is caused by a polymer depositing on the well walls during the etching process. For example,

when SiO

profile [151]. The tapering is caused by a polymer depositing on the well walls during the etching process. For example,

when SiO is etched using CF

is etched using CF gas, the CF

gas, the CF gas undergoes a gas phase reaction, where it breaks into CF

gas undergoes a gas phase reaction, where it breaks into CF gas and F atoms. The CF

gas and F atoms. The CF gas

then undergoes a surface deposition reaction with the SiO

gas

then undergoes a surface deposition reaction with the SiO . In order to simulate this phenomenon in the presented LS framework,

a model from [113] is implemented. It deals with an etching process with a simple chemistry such as a pure CF

. In order to simulate this phenomenon in the presented LS framework,

a model from [113] is implemented. It deals with an etching process with a simple chemistry such as a pure CF etch of SiO

etch of SiO under

Ar

under

Ar bombardment and polymer inhibition. The model parameters and constants which are implemented here can be found in [113].

bombardment and polymer inhibition. The model parameters and constants which are implemented here can be found in [113].

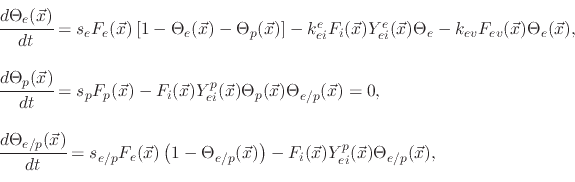

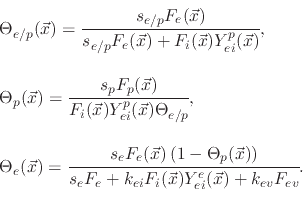

The model suggests three surface coverages, one for the etchant

, one for the polymer

, one for the polymer

,

and one for the active sites on the polymer coverage

,

and one for the active sites on the polymer coverage

. The coverages are found using

. The coverages are found using

|

(194) |

where

,

,

, and

, and

are the total fluxes of the ion, etchant, and polymer, respectively and

are the total fluxes of the ion, etchant, and polymer, respectively and

is an evaporation flux which is proportional to

is an evaporation flux which is proportional to

and temperature dependent. The constants

and temperature dependent. The constants  ,

,  , and

, and  are the sticking coefficients of the etchant on SiO

are the sticking coefficients of the etchant on SiO , polymer on SiO

, polymer on SiO , and etchant

on the deposited polymer, respectively.

, and etchant

on the deposited polymer, respectively.

and

and

are etching yield functions.

are etching yield functions.

Assuming steady state conditions, (5.35) can be used to find the surface coverages for each particle species

|

(195) |

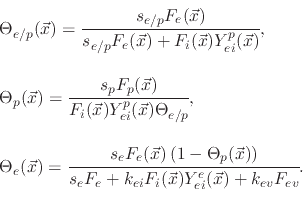

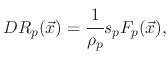

The deposition rate of the polymer gas onto the wafer surface is given by the polymer flux and the sticking coefficient

|

(196) |

where  is the polymer bulk density. The polymer can also be etched and this rate is given by the chemical sputtering rate

is the polymer bulk density. The polymer can also be etched and this rate is given by the chemical sputtering rate

|

(197) |

If the polymer deposition rate is higher than its etch rate, then no etching on the surface occurs, but rather a deposition whose rate is

given by

|

(198) |

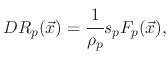

However, if the polymer deposition rate is lower than its etch rate, the film etching rate is given by

![$\displaystyle V_{SiO_{2}}(\vec{x})=-\cfrac{1}{\rho_{SiO_{2}}}\left[F_{i}(\vec{x...

...(\vec{x})

\left(1-\Theta_{e}(\vec{x})\right)+F_{ev}\Theta_{e}(\vec{x})\right],$](img712.png) |

(199) |

where

is the SiO

is the SiO bulk density and

bulk density and

accounts for the sputter yield of the silicon dioxide which is not covered by the etchant.

accounts for the sputter yield of the silicon dioxide which is not covered by the etchant.

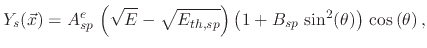

The threshold yield functions

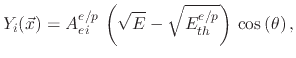

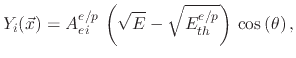

depend on the ion energies and the impact direction of the ions onto the surface. In the case of physical sputtering, the yield is given by

|

(200) |

where  is the impact angle,

is the impact angle,  is the sputtering threshold energy,

is the sputtering threshold energy,  is the ion impact energy, and

is the ion impact energy, and  is a sputtering yield

factor. For ion enhanced chemical etching, the yield function is given by

is a sputtering yield

factor. For ion enhanced chemical etching, the yield function is given by

|

(201) |

where

is the threshold energy and

is the threshold energy and

the etchant yield factor for ion enhanced chemical etching.

the etchant yield factor for ion enhanced chemical etching.

Figure 5.6 shows a simulation of the silicon dioxide etching process when various ion, etchant, and polymer fluxes are used. It is clear

that the ratio of etchant to polymer flux will decide how much polymer will be present on the sidewalls. Therefore, as the amount of polymer is decreased

with respect to the amount of etchant, shown from Figure 5.6a to 5.6c, the sidewalls show an increasing vertical

profile and higher etch rates. The simulation is performed through a 300nm diameter hole with an ideal mask for 80s. The profile is shown at 2s intervals.

This means that when etching the silicon dioxide layers for BiCS memory holes, an etchant should be used which produces

less deposition-inducing byproducts. When using C F

F , which was the etching process described in [113], the ratio of etchant to

polymer inhibitor flux is shown to be 2.5:1.

, which was the etching process described in [113], the ratio of etchant to

polymer inhibitor flux is shown to be 2.5:1.

The ratio of etchant to polymer flux is not the only process parameter governing the final etched profile. Another important factor is the sticking

coefficient of the inhibitor species. The process described by the model in [113] suggests a sticking probability of 0.26. However, it would be

beneficial for a process with a lower sticking probability to be used when sharp vertical etch profiles are required.

In [86]

a process using CF is suggested for SiO

is suggested for SiO etching for BiCS memory holes, which has the deposition precursor CF

etching for BiCS memory holes, which has the deposition precursor CF with a 0.0292 sticking probability.

Figure 5.7 shows how varying the sticking probability influences the etched profile when the flux of ion, etchant, and polymer

species are

with a 0.0292 sticking probability.

Figure 5.7 shows how varying the sticking probability influences the etched profile when the flux of ion, etchant, and polymer

species are

,

,

, and

, and

, respectively.

The simulations were performed through a 50nm opening, which is the approximate width required for etching BiCS memory holes, for 5s which should be sufficient for

the required depth (

, respectively.

The simulations were performed through a 50nm opening, which is the approximate width required for etching BiCS memory holes, for 5s which should be sufficient for

the required depth ( 33nm).

33nm).

L. Filipovic: Topography Simulation of Novel Processing Techniques

![]() profile [151]. The tapering is caused by a polymer depositing on the well walls during the etching process. For example,

when SiO

profile [151]. The tapering is caused by a polymer depositing on the well walls during the etching process. For example,

when SiO![]() is etched using CF

is etched using CF![]() gas, the CF

gas, the CF![]() gas undergoes a gas phase reaction, where it breaks into CF

gas undergoes a gas phase reaction, where it breaks into CF![]() gas and F atoms. The CF

gas and F atoms. The CF![]() gas

then undergoes a surface deposition reaction with the SiO

gas

then undergoes a surface deposition reaction with the SiO![]() . In order to simulate this phenomenon in the presented LS framework,

a model from [113] is implemented. It deals with an etching process with a simple chemistry such as a pure CF

. In order to simulate this phenomenon in the presented LS framework,

a model from [113] is implemented. It deals with an etching process with a simple chemistry such as a pure CF![]() etch of SiO

etch of SiO![]() under

Ar

under

Ar![]() bombardment and polymer inhibition. The model parameters and constants which are implemented here can be found in [113].

bombardment and polymer inhibition. The model parameters and constants which are implemented here can be found in [113].

![]() , one for the polymer

, one for the polymer

![]() ,

and one for the active sites on the polymer coverage

,

and one for the active sites on the polymer coverage

![]() . The coverages are found using

. The coverages are found using

![$\displaystyle V_{SiO_{2}}(\vec{x})=-\cfrac{1}{\rho_{SiO_{2}}}\left[F_{i}(\vec{x...

...(\vec{x})

\left(1-\Theta_{e}(\vec{x})\right)+F_{ev}\Theta_{e}(\vec{x})\right],$](img712.png)

![]() F

F![]() , which was the etching process described in [113], the ratio of etchant to

polymer inhibitor flux is shown to be 2.5:1.

, which was the etching process described in [113], the ratio of etchant to

polymer inhibitor flux is shown to be 2.5:1.

![\includegraphics[width=0.3\linewidth]{chapter_process_modeling/figures/SiO2_121.eps}](img726.png)

![\includegraphics[width=0.3\linewidth]{chapter_process_modeling/figures/SiO2_321.eps}](img727.png)

![\includegraphics[width=0.3\linewidth]{chapter_process_modeling/figures/SiO2_1021.eps}](img728.png)

![]() is suggested for SiO

is suggested for SiO![]() etching for BiCS memory holes, which has the deposition precursor CF

etching for BiCS memory holes, which has the deposition precursor CF![]() with a 0.0292 sticking probability.

Figure 5.7 shows how varying the sticking probability influences the etched profile when the flux of ion, etchant, and polymer

species are

with a 0.0292 sticking probability.

Figure 5.7 shows how varying the sticking probability influences the etched profile when the flux of ion, etchant, and polymer

species are

![]() ,

,

![]() , and

, and

![]() , respectively.

The simulations were performed through a 50nm opening, which is the approximate width required for etching BiCS memory holes, for 5s which should be sufficient for

the required depth (

, respectively.

The simulations were performed through a 50nm opening, which is the approximate width required for etching BiCS memory holes, for 5s which should be sufficient for

the required depth (![]() 33nm).

33nm).