|

|

||||

BiographyBernhard Stampfer, born in 1989 in Austria, studied at the Technische Universität Wien where he received the Bachelor’s degree (BSc) in Electrical Engineering (2013), the Diplomingenieur degree (Dipl.-Ing., MSc equivalent) in Microelectronics and Photonics (2016) and the Doctoral degree (Dr.techn., PhD equivalent) in 2020. Bernhard is employed at the Institute for Microelectronics as a post-doctoral researcher and his work is focused on the characterization of defects in semiconductor devices. |

|||||

Capacitance-Voltage Measurements using a Mercury Prober

Capacitance-voltage (CV) measurements are essential for studying the electrical properties of semiconductor devices. They allow to determine several key parameters such as doping concentration, junction depth, and interface quality.

To perform CV measurements, wafers or chips are commonly placed in a wafer prober and are electrically connected using needles. These needles are placed on metal test pads which are processed onto the samples. The key advantage of using a mercury prober instead of probe needles for this type of characterization is that it allows to measure samples which have not been processed to add metal electrode pads. This is important for studying novel materials or devices, as it eliminates the need for additional fabrication processes to create metal electrodes, which could alter, e.g., the interface characteristics. This method is also particularly useful for studying the properties of materials in cases, when it can be challenging to even create high-quality metallization.

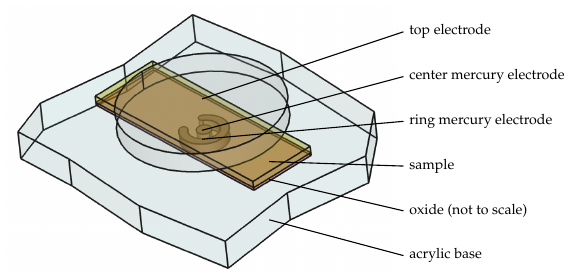

An illustration of the most relevant part of a mercury prober, as used at the Institute for Microelectronics, is shown in Fig. 1. The sample is placed with its oxide oriented towards the bottom on an acrylic base which contains two cut-outs for what will later be the mercury contacts. A solid metal top electrode is then lowered onto the sample. This can be used to contact the bulk of the chip, but also serves to press the sample against the acrylic base. A vacuum pump is then turned on to pull the mercury, which is contained in vials below the base, up against the sample. This forms a center contact and a separate ring contact on the oxide, which are accessible via connectors on the prober. After the measurements are complete, the vacuum pump can be turned off, and the mercury will return to the vials.

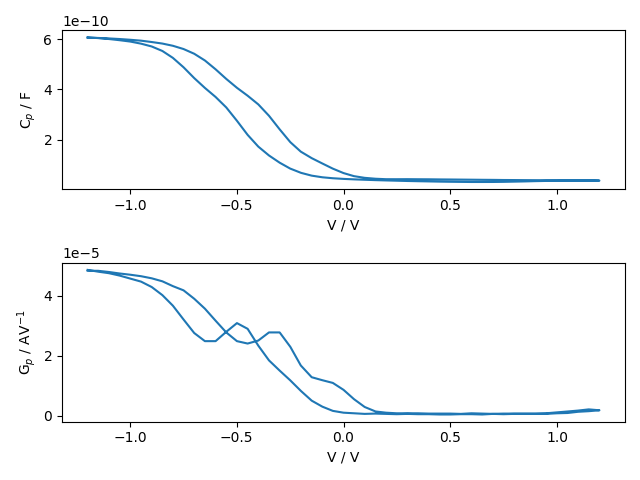

A hysteresis measurement, performed on a HfO2 sample, is shown in Fig. 2. Such measurements were conducted to investigate the influence of processing parameters on the interface quality.

Fig. 1: Schematic illustration of the relevant section of the mercury prober.

Fig. 2: Measurement of a HfO2 sample. Top: Capacitance, bottom: Conductance.