|

|

Biography

Vito Simonka was born in Murska Sobota, Slovenia, in 1991. He holds a bachelor's and master's degree in Physics from the University of Maribor, Slovenia. He joined the Institute for Microelectronics in August 2015 as a research assistent. His scientific interests include computational modeling for process TCAD, in particular SiC oxidation.

Modeling and Simulation of Directional-Dependent Silicon Carbide Oxidation

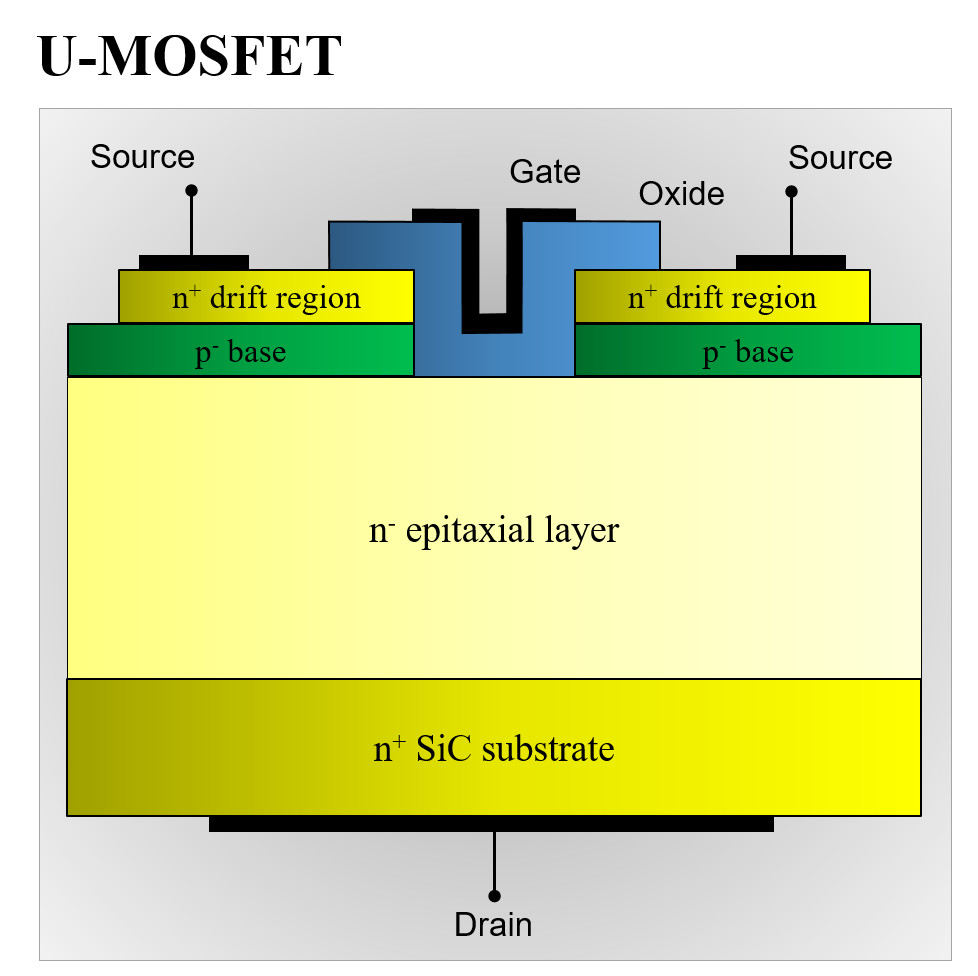

One of the major steps in silicon carbide (SiC) device fabrication technology is thermal oxidation. The grown silicon dioxide is one of the key aspects of device processing, as it serves as an insulating layer and/or as a gate oxide. The geometry of the oxide is essential for the characteristics of the devices, and accurate simulations of the oxidation process are therefore necessary. Our research focuses on SiC, as it is a highly attractive material for power device applications (e.g. MOSFETs) (see Fig. 1).

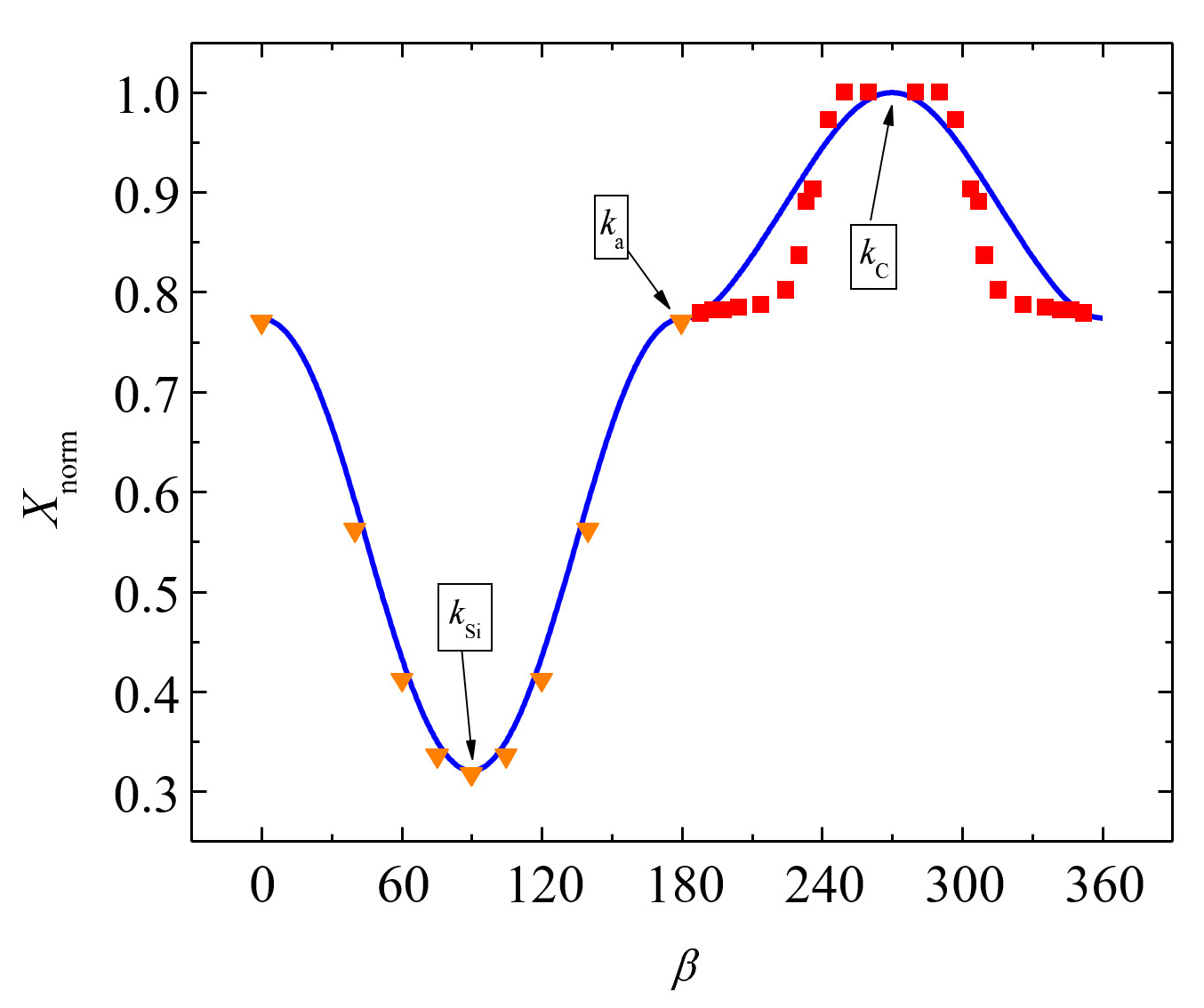

We have investigated the geometry of SiC and proposed a directional-dependent interpolation method for SiC oxidation growth rates. The method calculates growth rates in an arbitrary direction according to the four known rates in the directions of the Si- (0001), m- (1-100), a- (11-20) and C-faces (000-1). The proposed method is an essential step towards highly accurate three-dimensional oxidation growth simulations and improves our understanding of the anisotropic nature and oxidation mechanisms of SiC (see Fig. 2).

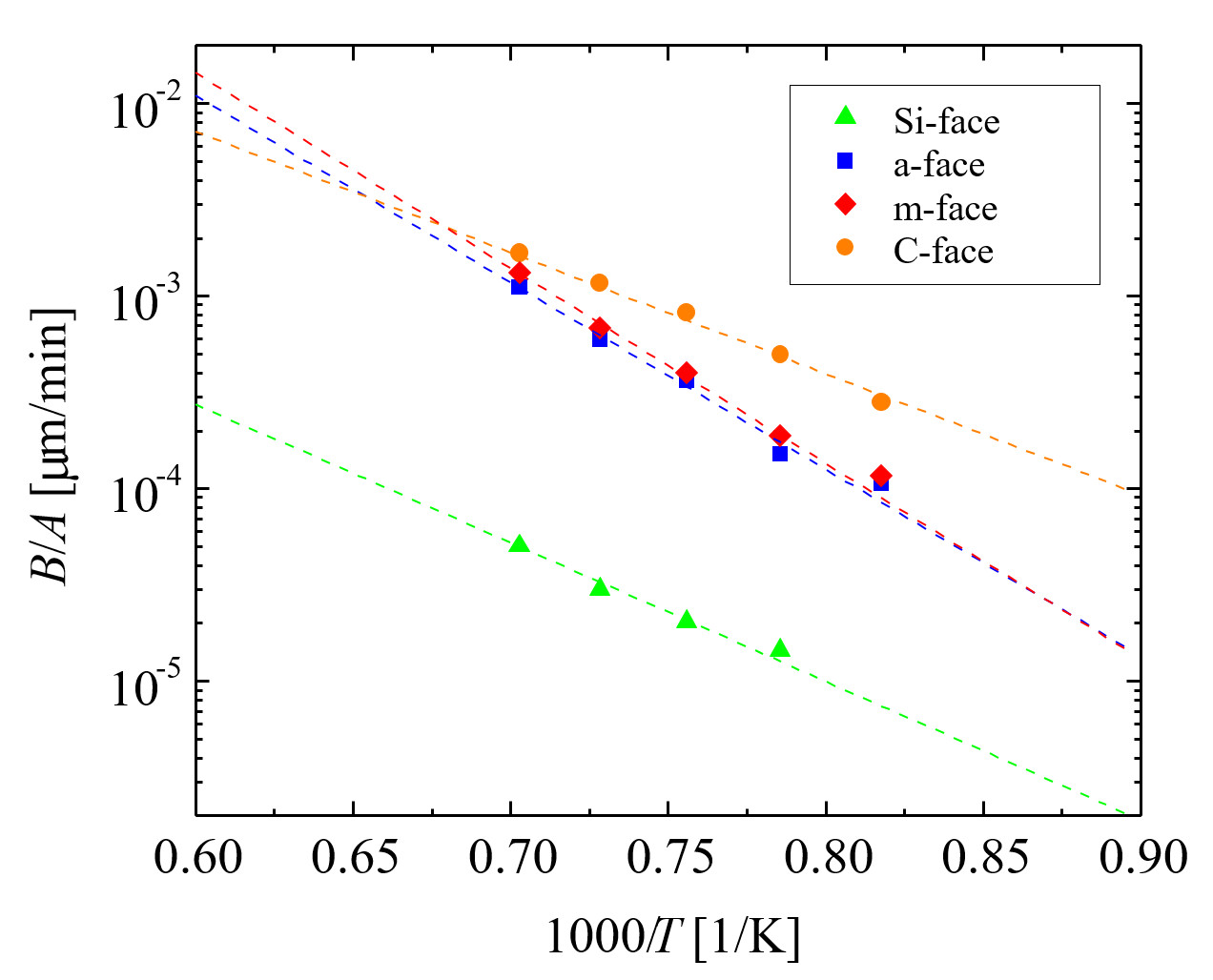

Previously available models of the oxidation growth mechanism were insufficient for simulating complex three-dimensional structures and were unable to correctly predict oxidation behavior for arbitrary crystal directions because of the inadequacy of the growth-rate coefficients. We have therefore provided a full set of growth rates to enable accurate two- and three-dimensional simulations of dry thermal oxidation of SiC (see Fig. 3). These are described by Arrhenius plots, to incorporate temperature dependency, and were obtained by fitting Massoud's empirical relation to the oxidation kinetics of the four different crystallographic faces.

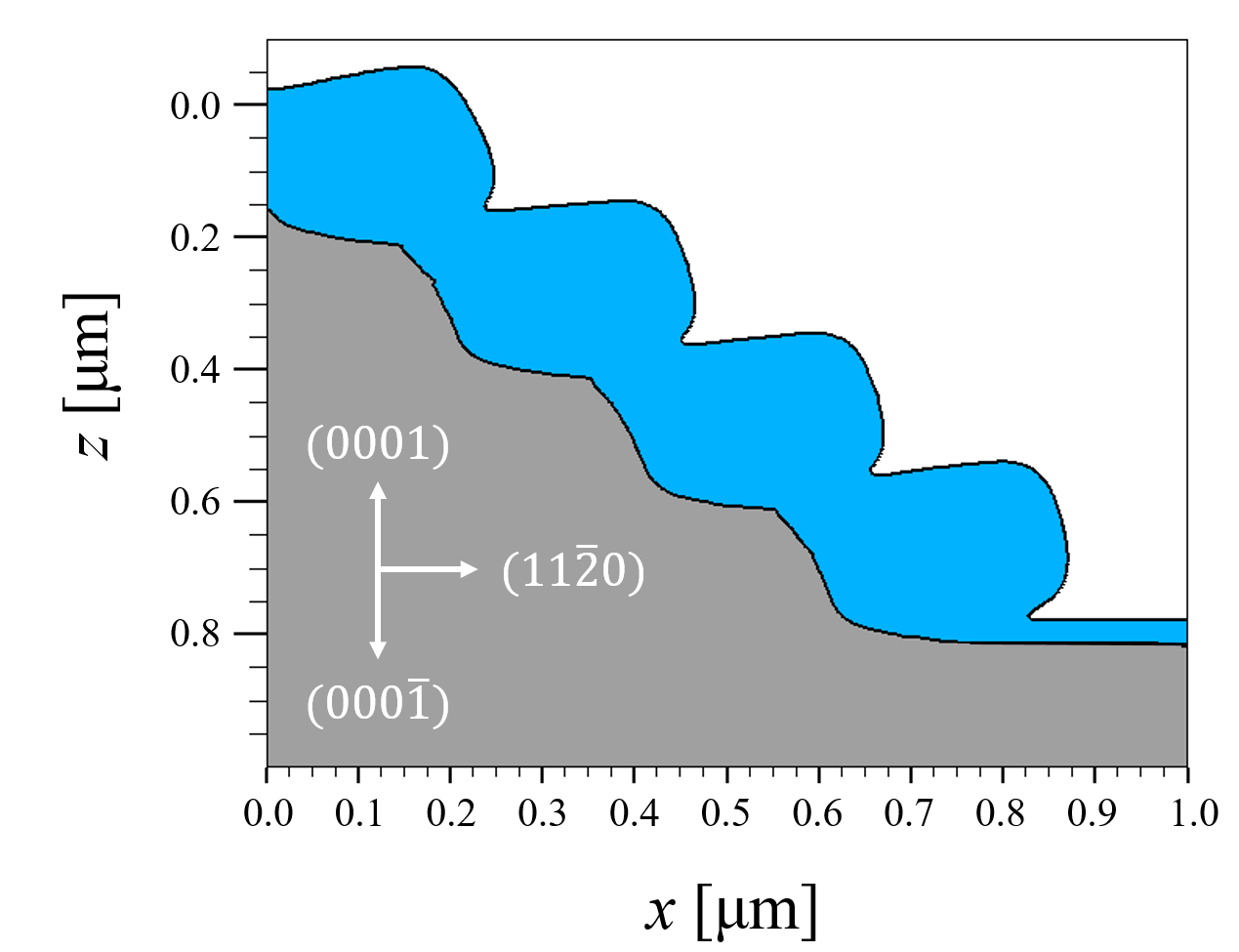

The temperature-dependent growth-rate coefficients for various crystal orientations, together with the proposed interpolation method, were implemented in Silvaco's Victory Process simulator. Several three- and two-dimensional simulations of SiC oxidation were performed (see Fig. 4) and showed great consistency with experimental findings.

We continued our research with another insufficiently investigated, but extremely important, step of device fabrication, namely post-implantation annealing. Currently, our primary objective is the investigation of the electrical activation of the implanted species in SiC, particularly boron and aluminium as acceptor-type and nitrogen and phosphorus as donor-type impurities.

Fig. 1: A schematic representation of a MOSFET with a U-shaped gate. This is an example of a device structure where the directional-dependent models we have developed are essential to predicting the geometry of the gate oxide correctly.

Fig. 2: Thermally grown oxide thickness as a function of angle in the x-y plane. The solid blue line represents the simulation performed with the proposed interpolation method, and the symbols refer to experimental measurements.

Fig. 3: Arrhenius plots of the oxidation growth-rate coefficients for the four different crystallographic faces. The symbols are the growth rates for the various oxidation temperatures obtained by fitting Massoud's empirical relation.

Fig. 4: An x-z cross-section of a three-dimensional simulation of SiC oxidation performed using the Victory Process simulator, including our proposed method and obtained parameters. The blue area indicates silicon dioxide and the gray refers to SiC.