|

|

Biography

Paul Manstetten was born in 1984 in Berlin, Germany. He studied Mechatronics at the University of Applied Sciences Regensburg (Dipl.-Ing.) and Computational Engineering at the University of Erlangen-Nuremberg (MSc). After three years as an application engineer for optical simulations at OSRAM Opto Semiconductors in Regensburg he joined the Institute for Microelectronics in 2015 as a project assistant. He finished his PhD studies (Dr.techn.) in 2018 and works as a postdoctoral researcher on high performance methods for semiconductor process simulation.

Sparse Surface Speed Evaluation Using an Iterative Partitioning Scheme

We focus on a surface evolution problem where the local surface speed depends on a computationally expensive scalar function with non-local properties. The local surface speed must be re-evaluated at each time step, even for non-moving parts of the surface, due to possible changes in properties in remote regions of the simulation domain. Our research is motivated by the high computational demand required for surface speed evaluation, something which is especially true for high-resolution surfaces. We present a method to evaluate the surface speed at only a sparse set of points in order to reduce the computational effort.

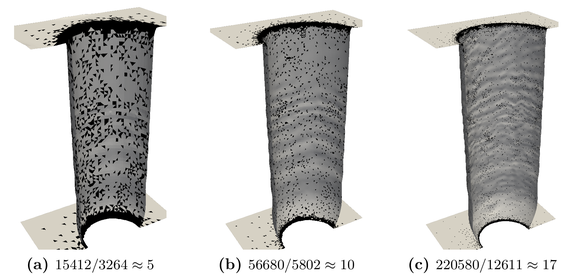

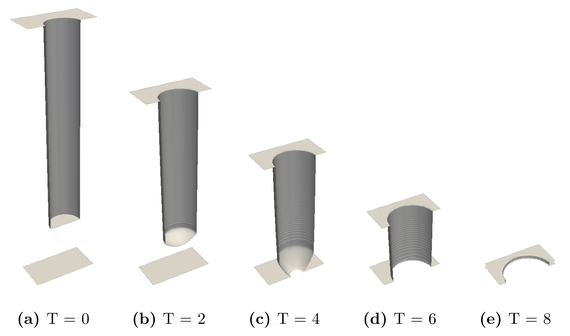

To evaluate our method, we use a generic etching simulation test case with a single material region, as visualized in Fig. 1. The local surface speed depends on the incident flux from a source plane above the surface. Fig. 2 illustrates the result of our proposed method. This sparse set of points (see the black triangles in Fig. 2) is generated according to application-specific requirements using an iterative partitioning scheme. We diffuse the result of a constant extrapolation in the neighborhood of the sparse points to obtain an approximation to a linear interpolation for the whole surface.

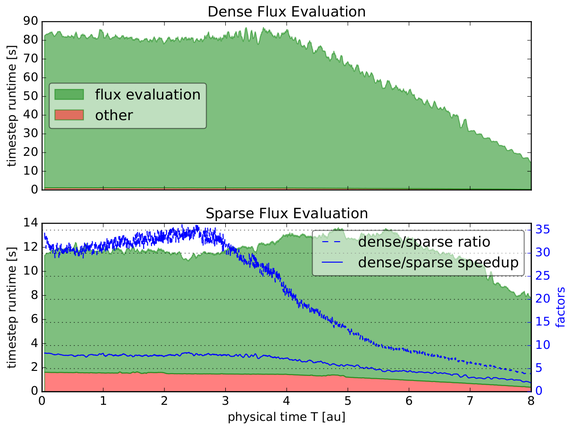

Fig. 3 plots the speed-up between a dense and sparse evaluation of the surface velocities for the highest-tested resolution throughout a full simulation run. Depending on the resolution of the surface, the speed-ups obtained range from 2 to 8 and the surface deviation is less than 3 grid-cells for all evaluated test cases.

Fig. 1: Cylindrical hole with a diameter of 1 and depth of 6 in a bulk region with a thickness of 8. Surface evolution during the simulation at times T = [0, 2, 4, 6, 8] (all units are arbitrary). The level-set resolution is 64 cells per unit length.

Fig. 2: Sparse set of triangles for different level-set resolutions at T = 4.5. The ratios between the total number of triangles and the sparse set of triangles (black) are denoted.

Fig. 3: Performance comparison for the highest resolution of 128 x 128 horizontal cells and up to 2,160 cells in a vertical direction.