If several materials are combined within a microstructure, mechanical forces

occur if the volumes of the different materials change. Several effects

may enforce volume expansion, for instance chemical reactions, phase

interchanges and recrystallization, mass migration, and thermal expansion and

contraction.

In this thesis, the mechanical stress due to thermal expansion is considered.

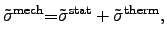

The mechanical stress

can be separated into a static and a thermal

stress component [33] as

can be separated into a static and a thermal

stress component [33] as

|

(3.23) |

where

represents the static stress component, which is

impressed and mostly fixed by the fabrication processes, for instance material

deposition, annealing, and packaging.

The thermal component of the stress

represents the static stress component, which is

impressed and mostly fixed by the fabrication processes, for instance material

deposition, annealing, and packaging.

The thermal component of the stress

is a transient

quantity influenced by the ambient temperature and other

state variables of the system. The corresponding hydrostatic pressure

is a transient

quantity influenced by the ambient temperature and other

state variables of the system. The corresponding hydrostatic pressure

is then defined as the trace of the mechanical stress tensor

is then defined as the trace of the mechanical stress tensor

,

,

for for |

(3.24) |

which represents an averaged value and can be used for significant comparisons,

as a figure of merit for optimization purposes, and to visualize the mechanical

stress in a microelectronic device structure.

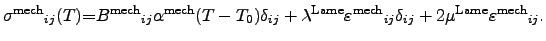

The local force density which acts on the material can be described by the

mechanical stress tensor

, which can be derived from the mechanical

strain tensor

, which can be derived from the mechanical

strain tensor

using the LAMÉ3.4 formalism to model

(2.109) as

using the LAMÉ3.4 formalism to model

(2.109) as

|

(3.25) |

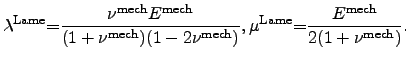

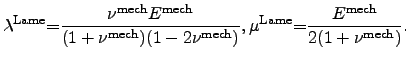

The quantities

and

and

are the LAMÉ constants, which can be

expressed by YOUNG's modulus

are the LAMÉ constants, which can be

expressed by YOUNG's modulus

and POISSON's ratio

and POISSON's ratio

[96,97] as

[96,97] as

|

(3.26) |

For orthotropic materials the number of independent components for the stiffness and stress tensor is

reduced due to energetic considerations and symmetry in the

crystals [202,96,97].

Hence, the number of independent components of the stiffness tensor (forth rank)

is reduced to nine and for the stress tensor (second rank) to six. Hence,

the mechanical problem can be expressed in terms of vectors and

matrices [202] according to the VOIGT notation.

Stefan Holzer

2007-11-19

![]() can be separated into a static and a thermal

stress component [33] as

can be separated into a static and a thermal

stress component [33] as

for

for![]() , which can be derived from the mechanical

strain tensor

, which can be derived from the mechanical

strain tensor

![]() using the LAMÉ3.4 formalism to model

(2.109) as

using the LAMÉ3.4 formalism to model

(2.109) as