Next: 2.6 Electrical Test

Up: 2. The Processing Chain

Previous: 2.4 Mask Generation

Subsections

2.5 Fabrication

In the following subsections an overview over the different process steps, a

wafer undergoes during its fabrication in the clean-room, is given.

A semiconductor manufacturing process differs markedly from other

processes. In many other types of processing plants, the material being

processed moves through the plant in a fairly simple, straightforward, and

well-integrated manner. Despite the fact that the processing flow of this

material is straightforward and linear, a flow chart depicting the process

will usually be quite complicated.

Contrast this with a semiconductor manufacturing process, which can be described

very easily with a linear processing flow chart, but whose work-in-process

(WIP) moving through the plant will follow complex paths, crisscrossing back

and forth in intricate patterns.

During wafer processing - i.e. in the semiconductor fabrication clean-room -

the integrated circuitry is formed at the surface of the single crystal

silicon wafer by numerous repetitive micro-lithographic, deposition,

diffusion, and etching steps, until it is finished. During this processing,

depending on the complexity of the technology, a set of about fifteen up

to more than thirty-five separate wafer processing cycles (which form modules

like gate module, LDD module, metal module and so on), including the

associated lithography step, were performed. An expanded flow chart of one of

these cycles appears as shown in Figure 2.8.

Figure 2.8:

Expanded flow chart of the wafer

fabrication cycle comprising one alignment step and the associated

processing

|

Here it can be seen that the wafer will iterate through this inner circle as

many times as there are masks(alignments)2.1 for adding new circuitry.

Micro-lithography is the process of defining useful shapes on the surface of a

semiconductor wafer. Typically this consists of a patterned exposure into some

sort of photosensitive material already deposited on the wafer. A variety of

processes that directly pattern the wafer are possible, such as directly

writing on the wafer with an electron beam, or nanoimprinting structures with

stamps, but at this time none is in use for high volume semiconductor

manufacturing.

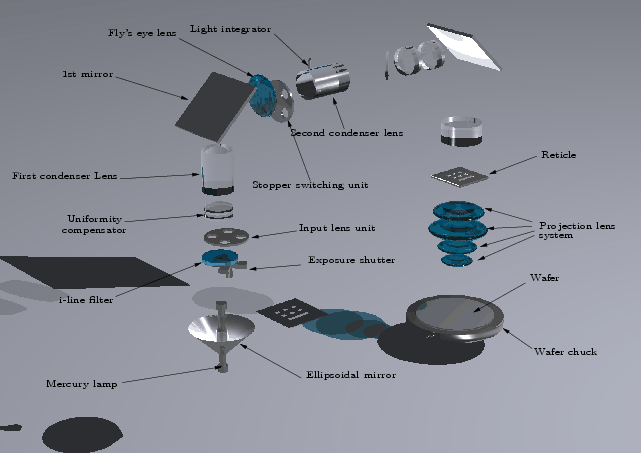

The imaging basics of optical lithography have been outlined in

Section 2.4 already. Figure 2.5.2 shows the principal

components of the illumination system of a typical i-line

stepper [43] practical for structure sizes down to 350nm.

Figure 2.9:

Schematic view of the main components of the illumination

system of a lithography tool

|

A detailed description of the lithography process and its modeling basics can

be found in [44].

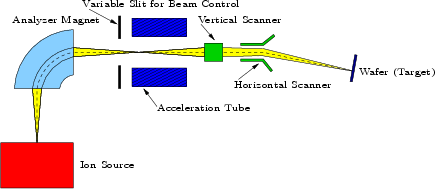

Ion implantation is a process whereby energetic dopant ions are made to

impinge on a silicon or other target, resulting in the penetration of these

ions below the target surface and thereby giving rise to controlled,

predictable dopant distributions. Low implant energy produces dopant

distributions near the surface such as are required for MOS source and drain

regions, or bipolar emitter regions. High energies produce deeply implanted

dopant profiles as required for CMOS retrograde wells and buried

layers. The provision of wafer cooling during implant allows the use of

photo resist masks to laterally control the location of dopant regions, an

inevitable feature for the production of CMOS devices. Similarly,

topographical features of the device, such as a gate stack, may be used to

impose additional masked regions to the implant, thereby allowing for the

production of cost- and yield-effective, self-aligned doping regions.

A detailed description of the physics of this process step can be found

in, e.g., [45],[46],[47],[48].

The general implanter schematic is shown in Figure 2.10.

Figure 2.10:

General schematic of an ion implantation equipment

|

Diffusion is a key task of semiconductor wafer processing. Although

dopants are generally introduced into a wafer by ion implantation, rather than

thermally in a furnace, there is unavoidable diffusion of the dopants during

any high temperature process step. The models in this area can be categorized

into two major approaches, namely, the continuum theory of Fick's diffusion

equation and the atomistic theory.

The continuum theory requires the solution of Fick's diffusion equation,

generally with constant values for the diffusion coefficient and is adequate

for low dopant concentrations. When the doping concentrations are high, the

diffusion profiles may exhibit anomalous diffusion behavior and a simple form

of Fick's law cannot be applied, because the diffusion coefficient becomes

concentration dependent. The picture then becomes considerably more

complicated and requires an atomistic approach which studies the interactions

between native point defects (vacancies and interstitials) and dopant

atoms. The underlying idea behind all this is that the dopant atoms mostly

dissolve substitutionally in the lattice. Only through interactions with

native point defects are the dopant atoms able to jump form one site to

another, effecting long-range diffusion.

Due to the agitation of the lattice by phonons some of the defects can wander

throughout the lattice. For a simple cubic lattice this diffusion of defects

can be understood by considering the jump process between two adjacent (100)

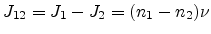

planes, 1 and 2. If the lattice planes contain  and

and  defects per

unit surface area, respectively, and the jump rate in either direction is

given by

defects per

unit surface area, respectively, and the jump rate in either direction is

given by  then the number of defects per unit surface area jumping form

plane 1 to 2 in time

then the number of defects per unit surface area jumping form

plane 1 to 2 in time  is

is

. For the same jump probability

in either direction, the net flux of dopants from plane 1 to 2

. For the same jump probability

in either direction, the net flux of dopants from plane 1 to 2  , can

be written as

, can

be written as

|

(2.6) |

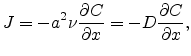

For a small lattice constant  and assuming that the number of defects

changes slowly with distance x (continuum approximation), the above flux can be written as

and assuming that the number of defects

changes slowly with distance x (continuum approximation), the above flux can be written as

|

(2.7) |

The defect concentration per unit volume  ,

(2.7) becomes

,

(2.7) becomes

|

(2.8) |

where

is the diffusion coefficient or diffusivity. The above

equation is Fick's first law of diffusion.

is the diffusion coefficient or diffusivity. The above

equation is Fick's first law of diffusion.

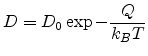

|

(2.9) |

where  is the activation energy.

is the activation energy.  is just

is just  , and

, and  is

proportional to the Debye frequency.

is

proportional to the Debye frequency.

A more detailed description of the theory of diffusion in semiconductors can

be found in [49],[50] and [51].

A variety of materials can be deposited by chemical vapor deposition

(CVD). Some typical materials are silicon nitride ( ), silicon dioxide

(

), silicon dioxide

( ), TEOS (

), TEOS (

), polycrystalline silicon, and various

metals. Depending on the particular deposition method, the temperature varies

from about

), polycrystalline silicon, and various

metals. Depending on the particular deposition method, the temperature varies

from about

up to

up to

. Additionally the pressure range may vary

significantly which differentiates atmospheric pressure chemical vapor

deposition (APCVD) from low pressure chemical vapor deposition (LPCVD). A

typical characteristic of the deposition process is the deposition rate

[nm/min]. Film deposition is used to deposit other materials on top of the

silicon wafer. These materials are necessary to build functional parts of the

devices (PMOS, NMOS,Bipolar Transistor) and their interconnects in the

integrated circuit.

. Additionally the pressure range may vary

significantly which differentiates atmospheric pressure chemical vapor

deposition (APCVD) from low pressure chemical vapor deposition (LPCVD). A

typical characteristic of the deposition process is the deposition rate

[nm/min]. Film deposition is used to deposit other materials on top of the

silicon wafer. These materials are necessary to build functional parts of the

devices (PMOS, NMOS,Bipolar Transistor) and their interconnects in the

integrated circuit.

For simulation, deposition is performed by geometry operations, where the

deposition rate may vary locally. Details about different simulation

approaches for deposition can be found in [52], [53] and [54].

Etching can be subdivided into two main categories, isotropic and anisotropic etching.

This category describes etching rates which are independent of

direction. Isotropic etching is usually performed by means of wet chemistry and the

wafer is immersed into a reactive solution. The etchant species diffuses

towards the wafer surface, dissolution of the specific material takes place,

and the generated products separate in turn by diffusion from the surface [55]. The

advantages of wet etching are the possible high selectivity for specific

materials and the low damage to the substrate.

A typical anisotropic method is reactive ion etching (RIE) [56]. Here ions are

accelerated through a Chlorine- or Fluorine-based-plasma towards the wafer

surface. The Chlorine (or Fluorine) penetration into the silicon surface is

strongly enhanced by the ion bombardment. Since vertical surfaces are less

exposed to the ions, a large ratio in the etching rates can be

obtained. Furthermore (especially for deep trench etching), passivation of the

etched sidewalls is obtained by polymerization of some components of the

etching chemistry at the sidewalls. Thus only the bottom of the advancing

etching front which is exposed to the ion bombardment is free of these

polymers and, therefore, a strong anisotropy of the etched structure can be

obtained. One drawbacks of the method is the possible damage to the silicon

substrate due to the high energy of the argon ions. Furthermore, the excitation

of the plasma field with an RF electromagnetic field induces potentials in the

interconnect wires contacting e.g CMOS transistor gates and subsequently

damaging the gate oxide of the CMOS transistors (antenna effect).

Footnotes

- ... masks(alignments)2.1

- One has to carefully

distinguish between the terms ``mask'' and ``alignment''. A mask is the

physical reticle for the illumination process. An alignment is the group of

steps performed in a lithography track as shown in Figure 2.8 in

the box. The number of masks and alignments is normally not equal,

because certain reticles may be used for more than one alignment.

Next: 2.6 Electrical Test

Up: 2. The Processing Chain

Previous: 2.4 Mask Generation

R. Minixhofer: Integrating Technology Simulation

into the Semiconductor Manufacturing Environment

![\includegraphics[width=1.5\textwidth]{figures/wafer_cycle.2.ps}](img79.png)

![\includegraphics[width=1.5\textwidth]{figures/wafer_cycle.2.ps}](img79.png)