Next: 4. Doping of Group-IV-Based

Up: Dissertation Robert Wittmann

Previous: 2. Semiconductor Doping Technology

Subsections

3. Simulation of Ion Implantation

There are two methods, the analytical and the Monte Carlo method, which are

commonly used in modern TCAD tools for the simulation of ion implantation

processes. Mainly increasing accuracy requirements due to the continued

downscaling of device dimensions necessitate the transition from the simple

analytical simulation of ion implantation to the particle-based Monte Carlo

simulation for more and more applications. This chapter outlines fundamental

modeling concepts required for the physically based simulation of doping profiles.

The basic idea of the analytical approach is that the doping profile can be

approximated by a statistical distribution

function [45,46,42,47].

This function depends on a set of parameters which can be expressed by

characteristic parameters of the implanted dopant distribution, for instance,

the mean projected range  . The characteristic parameters, the so-called

moments, can be extracted from Monte Carlo calculation results or from

measured doping profiles. One-dimensional distribution functions can be

combined to multi-dimensional profiles by a convolution method which takes

a dose matching rule and numerical scaling into account. The analytical

simulation of profiles requires relatively little CPU-time, even in two and

three dimensions.

. The characteristic parameters, the so-called

moments, can be extracted from Monte Carlo calculation results or from

measured doping profiles. One-dimensional distribution functions can be

combined to multi-dimensional profiles by a convolution method which takes

a dose matching rule and numerical scaling into account. The analytical

simulation of profiles requires relatively little CPU-time, even in two and

three dimensions.

Due to the simplicity of the underlying concept, analytical implantation

tools cannot accurately predict doping profiles for complex targets, for

instance, multilayer targets or advanced devices with junction depths in

the range of a few nanometers. In a compound target like SiGe, range

predictions will be still worse, because the doping profiles additionally

depend on the germanium fraction of the alloy. In contrast to that, the

physics-based Monte Carlo method uses an atomistic approach and, therefore,

is able to simulate the channeling effect and the accumulation of point

defects during the implantation process in crystalline targets, as well as, e.g.,

shadowing effects arising from mask edges [15,17,42].

The Monte Carlo method imitates the implantation process by computing a large

number of individual ion trajectories in the target. The three-dimensional device

structures can be complex, with the only limitation being the computer memory

size which must hold all the interaction details of the target. The underlying

physical models are applicable for a wide range of implantation conditions

without the need for an additional calibration.

One drawback of the Monte Carlo method are long computing times, which is the

main reason why the use of Monte Carlo implantation tools is usually

avoided in technology optimization. However, the capability of accurately

predicting doping profiles can significantly reduce the development time for

a new CMOS technology. In particular next generation technology nodes in the

deep sub-100nm regime will put high demands on the accuracy of TCAD tools.

3.1 Physical Models

This chapter outlines the fundamental physics associated with the penetration

of energetic ions into solids. The moving ions lose energy to the solid, create

point defects, and after stopping they produce the final distribution in the

target. The Monte Carlo modeling of ion implantation allows the incorporation

of arbitarily complex physical models at an atomic level.

An ion which penetrates into a target loses energy constantly to the sea of

electrons. It may go many atomic layers, before there is a collision with a

target atom which is hard enough to displace that atom and create an interstitial

and vacancy pair. The energy required to push a target atom just far enough from

its lattice site so that it cannot pop back into its empty site is the

displacement energy  , which is approximately 15eV in silicon.

Fig. 3.1 shows different scenarios which can arise for ions shot into a

crystalline target material.

, which is approximately 15eV in silicon.

Fig. 3.1 shows different scenarios which can arise for ions shot into a

crystalline target material.

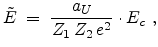

Assume an incident ion with atomic number  and energy

and energy  has a collision

with a target atom of atomic number

has a collision

with a target atom of atomic number  . After the collision the incident atom

has energy

. After the collision the incident atom

has energy  and the struck atom has energy

and the struck atom has energy  . A displacement

occurs if

. A displacement

occurs if  , so that the atom

, so that the atom  has enough energy to leave the

site. A vacancy occurs if both

has enough energy to leave the

site. A vacancy occurs if both  and

and  . Both atoms

then become moving atoms of the cascade. If

. Both atoms

then become moving atoms of the cascade. If  , then the atom

, then the atom  does not have enough energy and it will vibrate back to its site releasing

does not have enough energy and it will vibrate back to its site releasing

as phonons. If

as phonons. If  ,

,  , and

, and  , then the

incoming atom remain at the site and the collision is called a replacement

collision with

, then the

incoming atom remain at the site and the collision is called a replacement

collision with  released as phonons. This type of collision is common in

single element targets with large recoil cascades. If

released as phonons. This type of collision is common in

single element targets with large recoil cascades. If  ,

,  ,

and

,

and

, then

, then  becomes an interstitial atom.

becomes an interstitial atom.

Figure 3.1:

The incident ions 'make way' for themselves by knocking

the target atoms out of their lattice sites, whereas recoil cascades are generated.

![\resizebox{0.64\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/damage}}}](img235.png) |

Figure 3.2:

Principle of the Monte Carlo simulation method.

|

|

Ziegler et al. have demonstrated in [16] that the Monte Carlo

calculation of ion trajectories is a very feasible way for accurately simulating

the final ion distribution in crystalline silicon. Typically, Monte Carlo

programs calculate a large number of individual particle trajectories in a target.

Each particle history begins with a random starting position within the implantation

window, a given direction, and an ion beam energy  . Fig. 3.2 depicts

that a particle changes its direction as a result of nuclear collision events

and moves in straight free-flight-paths between collisions. The kinetic energy of

the particle is reduced as a result of nuclear and electronic energy losses, and

the history is terminated either when the energy drops below a specified value

. Fig. 3.2 depicts

that a particle changes its direction as a result of nuclear collision events

and moves in straight free-flight-paths between collisions. The kinetic energy of

the particle is reduced as a result of nuclear and electronic energy losses, and

the history is terminated either when the energy drops below a specified value

or when the particle leaves the simulation domain.

The rate at which an ion loses energy depends on the target atom density

or when the particle leaves the simulation domain.

The rate at which an ion loses energy depends on the target atom density  (in

cm

(in

cm ) and on the nuclear and electronic stopping powers

) and on the nuclear and electronic stopping powers  and

and  (in eVcm

(in eVcm ),

),

![$\displaystyle \frac{\mathrm{d}E}{\mathrm{d}x}\; =\; - N_T\; \left[ S_n(E) + S_e(E) \right] \;.$](img240.png) |

(3.1) |

The nuclear and electronic stopping powers are assumed to be independent and

both are in general functions of energy.

3.1.2 Binary Collision Approximation

The interaction of the moving ion with an atomic nucleus of the target (nuclear

stopping) can be treated as an elastic collision process, whereas the

interaction with the electrons can be treated as an inelastic process without

any scattering effects (electronic stopping). The binary collision approximation

(BCA) assumes that only two charged particles, the moving ion (atomic number

, mass

, mass  , kinetic energy

, kinetic energy  ) and one target atom (atomic number

) and one target atom (atomic number

, mass

, mass  ) are involved in one scattering process. While the moving

particle

) are involved in one scattering process. While the moving

particle  passes and is deflected, the stationary particle

passes and is deflected, the stationary particle  recoils

or at least activates thermal lattice vibrations. The distance between the

incident direction and the stationary particle is the impact parameter

recoils

or at least activates thermal lattice vibrations. The distance between the

incident direction and the stationary particle is the impact parameter  .

Fig. 3.3 shows the scattering variables in a two-body collision.

The unknown velocities

.

Fig. 3.3 shows the scattering variables in a two-body collision.

The unknown velocities  ,

,  and directions

and directions  ,

,  from

the incident direction after the collision event can be found from the

conservation of energy (3.2) and momentum (3.3),

(3.4) in the laboratory system.

from

the incident direction after the collision event can be found from the

conservation of energy (3.2) and momentum (3.3),

(3.4) in the laboratory system.

Figure 3.3:

Classical two particle scattering process in the

laboratory system and in the center-of-mass system.

![\resizebox{1.1\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/binscatter}}}](img247.png) |

For solving this two-body problem it is convenient to transform the scattering

process from the laboratory coordinates to the center-of-mass coordinate (CM)

system of ion and target atom. In Fig. 3.3, the CM system moves with

constant velocity  to the right. Equation (3.5) defines

to the right. Equation (3.5) defines  in such

a way that the total momentum of the CM system becomes zero. The basic reason

for this transformation is that the CM system reduces any two-body problem to

a one-body problem, because the total momentum of the particles is always zero

and the paths of the two particles are symmetric as shown in Fig. 3.3.

The single particle has the initial kinetic energy

in such

a way that the total momentum of the CM system becomes zero. The basic reason

for this transformation is that the CM system reduces any two-body problem to

a one-body problem, because the total momentum of the particles is always zero

and the paths of the two particles are symmetric as shown in Fig. 3.3.

The single particle has the initial kinetic energy  (3.6) and moves

with a reduced mass

(3.6) and moves

with a reduced mass  (3.7) and velocity

(3.7) and velocity  in a stationary potential

V(r) which is centered at the origin of the CM coordinates.

in a stationary potential

V(r) which is centered at the origin of the CM coordinates.

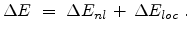

Ziegler derivates the particle scattering path by using Lagrangian mechanics in

polar coordinates in [17]. The result is the famous ``scattering

integral'' (3.8) which allows to evaluate the scattering angle  in the CM system. The angle

in the CM system. The angle  depends on the energy

depends on the energy  , the interatomic

potential

, the interatomic

potential  , and the impact parameter

, and the impact parameter  . The distance of minimum approach

between the two particles is denoted as

. The distance of minimum approach

between the two particles is denoted as  (see Fig. 3.3), which is

determined by the real root of the denominator in (3.8).

(see Fig. 3.3), which is

determined by the real root of the denominator in (3.8).

|

(3.8) |

The inverse transformation leads to the scattering angle  of the ion

(3.9), the angle

of the ion

(3.9), the angle  of the recoil (3.10), and the loss in

energy of the ion,

of the recoil (3.10), and the loss in

energy of the ion,  , which is equal to the recoil energy (3.11).

, which is equal to the recoil energy (3.11).

The scattering integral (3.8) cannot be calculated analytically for

interatomic screening potentials and a numerical integration would be too

time-consuming, since a simulated ion undergoes typically 100 to 1000 collisions.

Solutions to this problem are to use an analytical approximation formula or a

lookup table method. The used method is of critical importance in terms of

accuracy and efficiency for the Monte Carlo calculation.

The only non-trivial quantity in equation (3.8) is the interaction

potential  between the ion and the target atom. The potential

between the ion and the target atom. The potential  is a repulsive Coulomb potential between the two positively charged nuclei,

which is screened by surrounding electrons. The effect of the electrons is

described by a dimensionless screening function

is a repulsive Coulomb potential between the two positively charged nuclei,

which is screened by surrounding electrons. The effect of the electrons is

described by a dimensionless screening function  which is less than

one.

which is less than

one.

|

(3.12) |

and

and  are the atomic numbers of the involved particles,

are the atomic numbers of the involved particles,  is

the elementary charge, and

is

the elementary charge, and

is the dielectric constant.

Well-known older screening functions are the Bohr potential [48],

the Thomas-Fermi potential [49], the Moliere [50],

and the Lenz-Jensen approximation [51]. Ziegler, Biersack, and Littmark

performed the calculation of the interatomic potentials for 522 atom pairs.

Based on these calculations they could derive the universal screening

potential which is suitable for arbitrary atom pairs [17].

is the dielectric constant.

Well-known older screening functions are the Bohr potential [48],

the Thomas-Fermi potential [49], the Moliere [50],

and the Lenz-Jensen approximation [51]. Ziegler, Biersack, and Littmark

performed the calculation of the interatomic potentials for 522 atom pairs.

Based on these calculations they could derive the universal screening

potential which is suitable for arbitrary atom pairs [17].

The equation (3.13) for the universal screening function  consists

of four fitted exponential terms and uses the scaled radius

consists

of four fitted exponential terms and uses the scaled radius  as its argument.

Ziegler, Biersack, and Littmark introduced the scaled radius

as its argument.

Ziegler, Biersack, and Littmark introduced the scaled radius  according to

(3.14), where

according to

(3.14), where  is the real radius,

is the real radius,  is the universal screening

length, and

is the universal screening

length, and

is the Bohr radius. In the

literature the universal potential is known as Ziegler-Biersack-Littmark (ZBL)

potential.

is the Bohr radius. In the

literature the universal potential is known as Ziegler-Biersack-Littmark (ZBL)

potential.

Figure 3.4:

Universal screening potential and other approximations.

![\resizebox{0.8\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/unipot}}}](img283.png) |

Table 3.1:

Debye temperature  and corresponding average vibration

amplitude

and corresponding average vibration

amplitude  .

.

| Method |

(K) (K) |

at 300K at 300K |

| Specific heat |

645 |

0.065 |

| Channeling experiment |

490 |

0.083 |

| Simulation of ion implantation |

450 |

0.090 |

|

Thermal vibrations displace the lattice atoms from their ideal lattice positions

and they have been identified as source of the dechanneling mechanism, unless

the crystalline target contains considerable damage [52,53].

The approximation of a spherically symmetric Gaussian distribution

can be used to describe the displacement of

atoms from their rest position.

can be used to describe the displacement of

atoms from their rest position.

![$\displaystyle f(\Delta x, \Delta y, \Delta z) = \frac{1}{\sqrt[3]{2\pi\sigma^2}...

...m{exp} \left(-\frac{\Delta x^2 + \Delta y^2 + \Delta z^2}{2\sigma^2}\right) .$](img286.png) |

(3.15) |

The standard deviation  of the atomic displacement

of the atomic displacement

from the rest position can be adjusted

according to the Debye theory [54], which is in good agreement

with X-ray diffraction experiments [55]. This theory uses an empirical

parameter, the Debye temperature

from the rest position can be adjusted

according to the Debye theory [54], which is in good agreement

with X-ray diffraction experiments [55]. This theory uses an empirical

parameter, the Debye temperature  , which can be determined with the aid of

specific heat measurements [56], by channeling experiments [57],

or by comparison of simulated profiles with SIMS data [58], as summarized

in Table 3.1 for silicon at a wafer temperature of 300K.

, which can be determined with the aid of

specific heat measurements [56], by channeling experiments [57],

or by comparison of simulated profiles with SIMS data [58], as summarized

in Table 3.1 for silicon at a wafer temperature of 300K.

Fig. 3.5 shows a sample size of 10000 atom vibration amplitudes which are used

for the Monte Carlo calculation of ion trajectories in MCIMPL-II. The simulator

uses an average vibration amplitude

according

to a Debye temperature of 490K to model the motion of the atoms in silicon.

Note that the random variates from the Gaussian distribution presented in

Fig. 3.5 are derived from a random-number generator which produces uniformly

distributed random variates in the interval

according

to a Debye temperature of 490K to model the motion of the atoms in silicon.

Note that the random variates from the Gaussian distribution presented in

Fig. 3.5 are derived from a random-number generator which produces uniformly

distributed random variates in the interval ![$ [0, 1]$](img289.png) . The fast polar method

is used to generate originally random variates in pairs from the normal distribution

contained in the interval

. The fast polar method

is used to generate originally random variates in pairs from the normal distribution

contained in the interval

![$ [-\infty, \infty]$](img290.png) with mean

with mean  and standard

deviation

and standard

deviation

, as described in [59].

, as described in [59].

Figure 3.5:

Gaussian distribution of the atom vibration amplitudes in

MCIMPL-II.

![\resizebox{0.8\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/atomvib}}}](img293.png) |

3.1.3 Electronic Stopping Power

The electronic stopping power of the target is complicated and not fully understood

up to now, since several physical processes contribute to the electronic energy

loss [16]:

- Direct kinetic energy transfer to target electrons, mainly due to

electron-electron collisions.

- Excitation of band- or conduction-electrons (effect on weakly bound or

non-localized target electrons).

- Excitation or ionization of target atoms (effect on localized electrons).

- Excitation, ionization, or electron-capture of the projectile.

The electronic stopping models used for Monte Carlo implantations into silicon

can be classified as non-local or local. While non-local models assume that the

electronic energy loss is independent of the relative positions of the ion and

the target atoms [60,16], local models take such a dependence

into account, using either the impact parameter of the collisions [61]

or the local electron concentration along the ion path [62].

Hobler et al. proposed an empirical electronic stopping model for the implantation

into crystalline silicon [63], which is based on the Lindhard electronic

stopping model and an impact parameter approach.

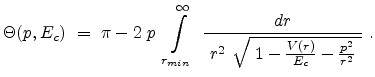

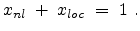

In the Hobler model the total electronic energy loss  is composed of a

non-local part which dominates in the case of large impact parameters (channeling

ions) and a local part which is considered at every collision.

is composed of a

non-local part which dominates in the case of large impact parameters (channeling

ions) and a local part which is considered at every collision.

|

(3.16) |

The non-local part

is proportional to the the path length

is proportional to the the path length  traveled by the ion between two nuclear collision events in a target material with

atomic density

traveled by the ion between two nuclear collision events in a target material with

atomic density  .

.

![$\displaystyle \Delta E_{nl} = N \; S_e \; \Delta R \cdot\left[ x_{nl} + x_{loc}...

...\frac{p_{max}}{a}\right) \mathrm{exp}\left(-\frac{p_{max}}{a}\right)\right] .$](img298.png) |

(3.17) |

The local part

is exponentially proportional to the impact parameter as proposed

by Oen and Robinson in [61].

is exponentially proportional to the impact parameter as proposed

by Oen and Robinson in [61].

|

(3.18) |

The term in equation (3.17) containing  approximates the local

electronic energy loss due to collisions with impact parameters larger than

approximates the local

electronic energy loss due to collisions with impact parameters larger than  .

The electronic stopping power

.

The electronic stopping power  is assumed to be velocity proportional

in (3.19). Lindhard et al. proposed the expression (3.20) for the

coefficient

is assumed to be velocity proportional

in (3.19). Lindhard et al. proposed the expression (3.20) for the

coefficient  [60], which considers the properties of the ion

species and the target material.

[60], which considers the properties of the ion

species and the target material.

and

and  are the charge and the mass of the implanted particle,

are the charge and the mass of the implanted particle,  is

the atomic charge in single-element targets,

is

the atomic charge in single-element targets,  is the Bohr radius, and

is the Bohr radius, and  the kinetic energy of the particle. The Lindhard correction factor

the kinetic energy of the particle. The Lindhard correction factor  is used to empirically adjust the strength of the electronic stopping.

The screening length

is used to empirically adjust the strength of the electronic stopping.

The screening length  is expressed by the value

is expressed by the value

in [61], where

in [61], where  is the screening length used for the interatomic

screening potential in (3.14). Hobler et al. multiplied the length by a

screening pre-factor

is the screening length used for the interatomic

screening potential in (3.14). Hobler et al. multiplied the length by a

screening pre-factor  according to

according to

|

(3.21) |

The parameters  and

and  are the non-local and the local fraction

of the total electronic stopping power which requires the relation (3.22)

to hold.

are the non-local and the local fraction

of the total electronic stopping power which requires the relation (3.22)

to hold.

|

(3.22) |

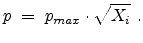

The non-local fraction  depends on the energy

depends on the energy  and can be modeled by

a power law,

and can be modeled by

a power law,

|

(3.23) |

Table 3.2:

Energy limits for the velocity proportional

electronic stopping power [42].

| Dopant species |

Energy limit (MeV) |

| Arsenic |

194.1 |

| Boron |

2.2 |

| Phosphorus |

28.0 |

|

where the empirical parameters  and

and  are the non-local pre-factor

and non-local power.

Lindhard indicated that the electronic stopping power

are the non-local pre-factor

and non-local power.

Lindhard indicated that the electronic stopping power  is only proportional

to the ion velocity up to a maximal energy which is shown for some important ion

species in Table 3.2.

is only proportional

to the ion velocity up to a maximal energy which is shown for some important ion

species in Table 3.2.

The drawback of the empirical Hobler model is that many parameters have to be

fitted, in particular for crystalline materials. Hobler has demonstrated for

boron implantations in crystalline silicon [64] that the accuracy

of the empirical model is better than that of the purely electron-density-based

model. The Hobler model requires less additional computational effort since the

impact parameter which is used by the BCA algorithm to determine the nuclear

energy loss can be applied to calculate the electronic energy loss. Both the

nuclear and the electronic stopping powers depend on the energy and contribute

to the total stopping. Fig. 3.6 demonstrates the slowing down of boron

ions with an initial energy of 40keV. Note that the nuclear stopping has its

maximum at 3keV and the electronic stopping dominates for higher energies.

Figure 3.6:

Average nuclear and electronic stopping powers

and

and  for a 40keV boron implantation into silicon, analyzed with

MCIMPL-II.

for a 40keV boron implantation into silicon, analyzed with

MCIMPL-II.

![\resizebox{0.77\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/energyloss}}}](img317.png) |

Summarizing, it can be said that the electronic stopping is dominant for higher

energies, lighter ions, and under channeling conditions.

3.1.4 Damage Generation

The nuclear stopping process of energetic ions in crystalline targets displaces

atoms from their lattice sites. If the ion implantation dose is high enough, a

continuous amorphous layer can be formed in a silicon wafer beneath the surface.

A so-called Frenkel pair or Frenkel defect is formed when a

displaced target atom forms an interstitial and leaves a vacancy behind at its

original lattice site [29]. The point defects in the target accumulate

during the implantation process and influence the trajectories of subsequently

implanted ions. In addition, the generated point defects cause a transient

enhanced diffusion (TED) effect of dopant atoms during the RTA annealing process.

Due to the fact that it is difficult to measure damage concentrations in crystals,

the simulation of implantation induced point defects as well as the identification

of amorphized regions in the device are very beneficial for modern CMOS process

engineering.

The generation of point defects can be modeled by the analytical modified

Kinchin-Pease model or by the computationally intensive Follow-Each-Recoil

method.

Modified Kinchin-Pease Model

The modified Kinchin-Pease model assumes that the number of displaced atoms

(Frenkel pairs) in a collision cascade is a function of the transferred

energy  from the ion to the primary recoil atom [65,66].

In this theory, the defect producing energy

from the ion to the primary recoil atom [65,66].

In this theory, the defect producing energy  is obtained from the kinetic

energy of the primary knock-on recoil, reduced for the electronic loss by all

recoils comprising the cascade. The recoils themselves are not individually

followed in this computationally fast approach. It was found in [63]

that experimental results can be well described by the modified Kinchin-Pease

model together with a model for point defect recombination. The defect

recombination which takes place in a recoil cascade can be modeled empirically

by using the local point defect concentration.

is obtained from the kinetic

energy of the primary knock-on recoil, reduced for the electronic loss by all

recoils comprising the cascade. The recoils themselves are not individually

followed in this computationally fast approach. It was found in [63]

that experimental results can be well described by the modified Kinchin-Pease

model together with a model for point defect recombination. The defect

recombination which takes place in a recoil cascade can be modeled empirically

by using the local point defect concentration.

The electronic energy loss is calculated according to Lindhard's

theory [67] using the analytical approximation of

Robinson [68] to the universal function

.

The ``damage energy''

.

The ``damage energy''  is calculated from the initial energy

is calculated from the initial energy  of the primary recoil by

of the primary recoil by

where  and

and  are the atomic number and mass of the recoil atoms, and the reduced

energy

are the atomic number and mass of the recoil atoms, and the reduced

energy

is a dimensionless quantity. The number of generated

Frenkel pairs

is a dimensionless quantity. The number of generated

Frenkel pairs  in a recoil cascade can be calculated from the energy

in a recoil cascade can be calculated from the energy  using a constant displacement efficiency

using a constant displacement efficiency

in the modified

Kinchin-Pease damage generation formula, given by

in the modified

Kinchin-Pease damage generation formula, given by

Figure 3.7:

Number of Frenkel pairs generated by a primary knock-on atom

in silicon assuming  eV, plotted for two different energy ranges.

eV, plotted for two different energy ranges.

|

|

The primary recoil atom produces only lattice vibrations if the damage energy

is below the displacement energy

is below the displacement energy  . The curves in

Fig. 3.7 show the number of produced point defects

. The curves in

Fig. 3.7 show the number of produced point defects  for

damage cascades in silicon as a function of the transferred energy

for

damage cascades in silicon as a function of the transferred energy  without considering pre-existing point defects, as calculated by the modified

Kinchin-Pease model.

without considering pre-existing point defects, as calculated by the modified

Kinchin-Pease model.

The recombination between interstitials and vacancies has to be taken into

account in order to realistically calculate the produced amount of point

defects [63]. The recombination within a collision cascade can be

described by a constant fraction  of Frenkel pairs surviving the

spontaneous self-annealing process due to beam-induced heating of the wafer.

If

of Frenkel pairs surviving the

spontaneous self-annealing process due to beam-induced heating of the wafer.

If  is the number of point defects generated in a recoil cascade,

then the average number of point defects surviving recombination within the

cascade is given by

is the number of point defects generated in a recoil cascade,

then the average number of point defects surviving recombination within the

cascade is given by

. The correction parameter

. The correction parameter

depends on the ion species since heavy ions produce damage more

efficiently by overlapping of large cascades than lighter ions. A light ion

produces typically small cascades due to small transfer energies, where

recombination becomes more likely. The recombination with point defects of

previously generated damage cascades can be included by an additional factor

depends on the ion species since heavy ions produce damage more

efficiently by overlapping of large cascades than lighter ions. A light ion

produces typically small cascades due to small transfer energies, where

recombination becomes more likely. The recombination with point defects of

previously generated damage cascades can be included by an additional factor

which depends on the recombination probability

which depends on the recombination probability  defined

in (3.33). The average number of stable point defects

defined

in (3.33). The average number of stable point defects  is linked to the number of generated point defects

is linked to the number of generated point defects  according to

according to

The factor  is obtained by considering the four possible cases for a

Frenkel pair having survived recombination within the recoil cascade. In the

first case, the generated Frenkel pair (both components) recombines with a

pre-existing Frenkel pair, which reduces the total number of Frenkel pairs

by one. The probability for this process is

is obtained by considering the four possible cases for a

Frenkel pair having survived recombination within the recoil cascade. In the

first case, the generated Frenkel pair (both components) recombines with a

pre-existing Frenkel pair, which reduces the total number of Frenkel pairs

by one. The probability for this process is  . In the second case,

which occurs with the probability

. In the second case,

which occurs with the probability

, the generated

Frenkel pair survives, resulting in an addditional Frenkel pair. In the

third and forth case either the interstitial or the vacancy survives while the

other one recombines, resulting in no change of the total Frenkel pair number.

Adding this changes with their probabilities yields

, the generated

Frenkel pair survives, resulting in an addditional Frenkel pair. In the

third and forth case either the interstitial or the vacancy survives while the

other one recombines, resulting in no change of the total Frenkel pair number.

Adding this changes with their probabilities yields

as the

net average fraction of point defects surviving recombination with previously

generated point defects.

The recombination probability

as the

net average fraction of point defects surviving recombination with previously

generated point defects.

The recombination probability  is proportional to the concentration

of already existing vacancies and interstitials and it has a species dependent

saturation level

is proportional to the concentration

of already existing vacancies and interstitials and it has a species dependent

saturation level  as given in (3.33). Assuming equal local

concentrations of vacancies and interstitials,

as given in (3.33). Assuming equal local

concentrations of vacancies and interstitials,  , the probability

, the probability

has to be equal to the probability of survival

has to be equal to the probability of survival

at

the saturation concentration, leading to

at

the saturation concentration, leading to

for

for

.

Substituting (3.32) and (3.33) into (3.31) and

assuming

.

Substituting (3.32) and (3.33) into (3.31) and

assuming  , the number of stable point defects

, the number of stable point defects  are finally

obtained by

are finally

obtained by

|

(3.34) |

In principle, the displaced atoms can be placed on tetrahedral interstitial sites

(tetrahedral interstitial model) [69], on random positions (random

model) [70], or on random positions within spheres around the

tetrahedral interstitial sites. In [63], Hobler et al. placed the

silicon interstitials on random positions within the maximum impact parameter

from the ion path in the plane perpendicular to the ion's direction

of motion. From the comparison of simulations and experiments they found that the

silicon interstitials are rather randomly distributed in the crystal lattice

than located at tetrahedral interstitial sites.

from the ion path in the plane perpendicular to the ion's direction

of motion. From the comparison of simulations and experiments they found that the

silicon interstitials are rather randomly distributed in the crystal lattice

than located at tetrahedral interstitial sites.

The modified Kinchin-Pease model can only estimate the number of vacancies

produced in a collision cascade and, therefore, this damage model assumes the

same local concentration for the interstitials. There is a small offset between

the local vacancy and interstitial concentrations, since a vacancy stays

at the position where the recoil has been generated whereas an interstitial

typically comes to rest somewhere slightly deeper in the target.

This results in an interstitial profile with its peak at a slightly deeper

position than the peak of the corresponding vacancies.

The Follow-Each-Recoil method calculates the trajectories of all recoiling

atoms in a collision cascade. In the full cascade simulation, the nuclear

and electronic loss of a recoil is calculated in the same way as for an

implanted ion just with different physical properties. This approach requires

a tremendous computational effort, since a cascade can be in the range of

thousand displaced atoms in silicon, as demonstrated for high energies of

the primary recoil in the right plot of Fig. 3.7.

The advantage of the Follow-Each-Recoil method is that the location of the

interstitials can be accurately calculated as well as pollution effects can

be estimated. A pollution occurs in a semiconductor device, for instance,

if implanted ions push oxygen atoms from an isolation layer into the active

area of the device [71].

For a rigorous study of doping profiles for advanced semiconductor devices it

is mandatory to consider crystalline materials and arbitrary three-dimensional

geometries. The Monte Carlo ion implantation simulator MCIMPL-II was used

for the simulation of doping profiles throughout this thesis. Therefore, a brief

description of the simulator is presented in this section. The simulator has

been developed on the basis of MCIMPL [15] at the Institute for

Microelectronics. In contrast to its predecessor, MCIMPL-II has a flexible

object-oriented architecture and uses the functionality of the Wafer-State-Server

library [72]. MCIMPL-II can be easier extended to new materials,

while MCIMPL was originally just designed for the implantation into silicon.

Hobler started the project in 1986 by implementing the fundamental physical

models and by calibrating the models for the most important dopant species used

in silicon technology [73]. Stippel extended the simulator to three

dimensions [74] and Bohmayr implemented the Trajectory-Split

method [75]. Hössinger included the Follow-Each-Recoil method

in MCIMPL [42]. When he designed MCIMPL-II, he replaced

the simple data management of MCIMPL by a better handling of the simulation

data for a fast point location in heavily non-planar device

structures [76]. In the scope of this work, the postprocessing

of raw Monte Carlo data in MCIMPL-II was improved, and a grid-generator was

implemented to allow a fast simulation of one-dimensional doping profiles

which is particularly necessary for calibration purposes.

The current status is that MCIMPL-II can be used for one- and three-dimensional

implantation applications. Two-dimensional applications can be modeled by using

two-and-a-half dimensional device geometries with a small depth dimension.

The simulator can handle arbitrarily shaped device structures including overhang

structures. The simulated structure can be composed of several amorphous and

crystalline material segments. Various amorphous materials can be simulated,

for instance, SiO , Si

, Si N

N , TiN, or TaN, which are typically used in

CMOS processing. Several crystalline material segments can also be used in one

simulation domain with the restriction that the crystal orientation has to be

identical in all segments. In this work the simulator has been extended from

crystalline silicon to Si

, TiN, or TaN, which are typically used in

CMOS processing. Several crystalline material segments can also be used in one

simulation domain with the restriction that the crystal orientation has to be

identical in all segments. In this work the simulator has been extended from

crystalline silicon to Si

Ge

Ge

alloys of arbitrary

germanium content in the range from silicon to germanium. Polycrystalline

materials are treated as amorphous materials in which the crystalline structure

of the grains is neglected. This is not really a restriction, since

low-resistivity polysilicon for gates or interconnects is usually processed by

deposition of amorphous silicon, followed by high-dose ion implantation doping,

and finishing annealing.

alloys of arbitrary

germanium content in the range from silicon to germanium. Polycrystalline

materials are treated as amorphous materials in which the crystalline structure

of the grains is neglected. This is not really a restriction, since

low-resistivity polysilicon for gates or interconnects is usually processed by

deposition of amorphous silicon, followed by high-dose ion implantation doping,

and finishing annealing.

The Monte Carlo calculation of ion trajectories in crystalline targets uses

substantially only two random processes. The first one is applied to achieve

equally distributed starting points of ion trajectories within the implantation

window and the second one is used to imitate the thermal vibrations of the

target atoms. While the simulated ion moves through the target the simulator

uses locally either a crystalline or an amorphous model for searching the next

collision partner of the ion. The application of the amorphous model in crystalline

targets is performed with a certain probability which depends on the amount of

already generated damage in the crystal. Thus the transition from the crystalline

to the amorphous state of a region is taken into account, which is caused by the

accumulation of point defects during the implantation process. Note that the

Monte Carlo simulation of ion implantation without consideration of damage is

a static problem where the passage of time plays no role. In consideration of

damage accumulation over time the Monte Carlo simulation becomes dynamic.

In order to improve the performance, the simulator uses histogram cells aligned

on an orthogonal grid to count the number of implanted ions and of generated

point defects. The doping or damage concentration within a cell is obtained by

the number of particles contained in the cell divided by the volume of the cell.

However, the ion implantation process is accurately simulated by computing a

large number of individual ion trajectories in the target. Being based on

appropriately scaled random numbers, the results obtained with the Monte Carlo

method are never exact, but they converge to the characteristics of the

underlying physical models by increasing the number  of simulated ions.

The statistical error of Monte Carlo results vanishes for a sample size

of simulated ions.

The statistical error of Monte Carlo results vanishes for a sample size

.

.

Figure 3.8:

Schematic diagram of the Monte Carlo simulation with MCIMPL-II.

![\resizebox{0.98\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/dataflow}}}](img362.png) |

The principle of simulator operation can be grouped into the following three

sections:

- Initialization of the internal data structures

- Physical Monte Carlo simulation of ion trajectories

- Transfer of the doping data to an unstructured grid

The input device structure for implantation is provided as a file in the WSS

(Wafer State Server) format [77], which contains all geometry and

material information of the simulation domain. Thereby the dimension of the

simulation is specified by the input WSS file. Additionally, the input file can

contain implantation data from previous implantation steps. The implantation

conditions and simulation parameters, for instance, the desired number of

simulated ions are specified by user defined command-line parameters.

A description of the simulator command-line interface is provided in [42].

Fig. 3.8 shows schematically the simplified simulation data flow from

the input file to the output file.

The simulation is started by initializing the histogram for the Monte Carlo

simulation. When histogram cells are set up, they are initialized with data from

previous implantation steps and they are continuously updated when damage is

generated by an ion. Thereby damage accumulation from several ion implantation

steps is automatically considered as well as damage accumulation within a single

implantation step. The incoming dopant ions are slowed down due to the nuclear

and electronic stopping power of the target material. The final position of an

implanted ion is reached where it has lost its kinetic energy.

After performing the Monte Carlo calculation of all ion trajectories, the dopants,

vacancies and interstitials are stored in histograms. A sophisticated

smoothing algorithm based on the Bernstein polynomial

approximation [78] is applied in order to reduce the statistical

fluctuation of raw Monte Carlo results.

The smoothed data are then translated from the internal orthogonal grid to an

unstructured destination grid. The resulting output file contains the smoothed

doping and damage profiles which include the implantation results of all already

performed implantation steps. This WSS file can then be visualized for analysis

purposes and/or it can be used as input file for the subsequent simulation of

annealing processes.

Figure 3.9:

Flow of data between the linked software components

of MCIMPL-II, consisting of MCIMPL-II Core, Wafer-State-Server, and DELINK.

![\resizebox{0.91\linewidth}{!}{\rotatebox{0}{\includegraphics[clip]{figures/dataflowII}}}](img363.png) |

The simulator makes use of the Wafer-State-Server functionality not only for

reading a WSS file (geometry and attributes request) or WSS file writing

(attributes update), but there is also a continuous interaction during the

simulation. When an ion moves through the simulation domain, the simulator

requires the material type information at the current position of the ion in

order to select the appropriate model for the next collision event.

The Wafer-State-Server performs a point location and delivers the desired

information to the simulator core unit. Lastly, the Wafer-State-Server

provides a gridder interface to integrate different grid generators with

the simulator. Fig. 3.9 shows the data flow during the three-dimensional

simulation of ion implantation in a more detailed way including the

Wafer-State-Server and the three-dimensional unstructured grid generator

DELINK [79]. A brief description of the Wafer-State-Server

based simulation environment and the WSS file format is provided in

Appendix A.

3.2.2 Calculation of Ion Trajectories

The core of the simulator performs the calculation of ion trajectories in a

three-dimensional manner independent of the dimension of the simulated device

structure. An ion trajectory is simulated by successively applying nuclear and

electronic stopping processes that slow down the ion motion (as described in

Section 3.1). Therefore it is necessary to locate atomic nuclei of

the target which collide with the ion projectile. After finding the location of

the next collision partner, the parameters of the nuclear and electronic stopping

models are determined. The partner dependent parameters for the stopping models

are the mass and charge of the target atom, the impact parameter, and the free

flight path length between two nuclear collisions. Several physical and numerical

models are involved in the trajectory calculation. Each material segment of the

simulation domain has assigned its own set of models.

A model set consists primarily of four models selected from the following model

classes:

- Partner selection model

- Nuclear scattering model

- Electronic stopping model

- Damage generation model

The starting points of the ions are equally distributed within a rectangular

implantation window lying in a plane somewhat above the surface of the

simulation domain. But instead of selecting the starting points completely

randomly, the implantation window is divided into equally sized subwindows and

one ion starts from each subwindow. The position of the ion within the subwindow

is randomly chosen. This procedure for determining the starting points provides

a better statistical equidistribution of the points. Another advantage is that

this procedure allows to define a time step for a transient simulation in a very

convenient way, which is required for the parallelization of the trajectory

calculation. The calculation of the ion trajectories for all subwindows is

performed within one time step.

The initial momentum of an ion is determined by the implantation conditions

energy, and tilt and twist angles. In addition a

divergence of the ion beam can be specified. When a three-dimensional

simulation is performed, the simulator assumes that the wafer rotation (twist

angle) of 0 is parallel to the x-axis, which means according to the

definition of the tilt and twist angle (see Section 2.2.3) that the

y-axis is parallel to the primary flat of the wafer.

is parallel to the x-axis, which means according to the

definition of the tilt and twist angle (see Section 2.2.3) that the

y-axis is parallel to the primary flat of the wafer.

Two different selection strategies exist for crystalline and amorphous materials.

In crystalline materials the atoms are placed around their crystal lattice sites

due to thermal vibrations. The selection of the target atom which takes part in

the next nuclear scattering process is depicted in the left sketch of Fig. 3.10.

The ion is located at the beginning of the free flight path  . The actual

collison partner among the potential atoms in the direction of motion is that atom

which leads to the smallest positive free flight path length with an impact parameter

. The actual

collison partner among the potential atoms in the direction of motion is that atom

which leads to the smallest positive free flight path length with an impact parameter

smaller than

smaller than  . The maximum impact parameter

. The maximum impact parameter  is in the order

of magnitude of half of the lattice constant. If two collision partners would lead

to almost the same free flight path lengths, the two partners are treated simultaneously

based on the BCA method. In this multiple collision the sum of the momenta

transferred to the target atoms in individual binary collisions with neighboring

atoms is assumed to be the total momentum transferred to the crystal.

is in the order

of magnitude of half of the lattice constant. If two collision partners would lead

to almost the same free flight path lengths, the two partners are treated simultaneously

based on the BCA method. In this multiple collision the sum of the momenta

transferred to the target atoms in individual binary collisions with neighboring

atoms is assumed to be the total momentum transferred to the crystal.

Figure 3.10:

Searching for the next collision partners in crystalline

materials (left) and cylinder which determines the partner in amorphous targets (right).

|

|

The amorphous partner selection model is based on the fact that the atoms in

amorphous materials are approximately equally distributed. Therefore only the

material density has to be considered by a cylinder with a radius of the maximum

impact parameter  and a length of the average free flight path

and a length of the average free flight path

(as shown in Fig. 3.10) which contains one target atom. The average

free flight path is defined according to

(as shown in Fig. 3.10) which contains one target atom. The average

free flight path is defined according to

|

(3.35) |

where  is the atom density in the target. This model uses a constant flight

path length

is the atom density in the target. This model uses a constant flight

path length

and the collision partner is placed in a circular area

with the radius

and the collision partner is placed in a circular area

with the radius  on a plane perpendicular to the direction of motion

with the distance

on a plane perpendicular to the direction of motion

with the distance

from the actual ion position. The actual amorphous

impact parameter

from the actual ion position. The actual amorphous

impact parameter  is calculated by using the realization

is calculated by using the realization  from the set of

uniformly distributed random numbers

from the set of

uniformly distributed random numbers

in the interval

in the interval

![$ [0, 1]$](img289.png) according to

according to

|

(3.36) |

The maximum impact parameter  is determined only by the target atom density:

is determined only by the target atom density:

![$\displaystyle p_{max} \;=\; \frac{1}{\sqrt[3]{N_T}} .$](img370.png) |

(3.37) |

Figure 3.11:

Monte Carlo simulation of 50 boron trajectories in crystalline

silicon using an energy of 10keV and a tilt of 7 .

.

|

|

Figure 3.12:

Final position of 100 boron atoms implanted with 10keV into silicon.

|

|

The nuclear stopping process is simulated with the physical BCA model which is

based on the universal ZBL potential (as described in Section 3.1.2). The BCA model

contains no tunable parameters and can be applied to all materials. The elastic

two-particle scattering process is approximated by its asymptotic behavior and

the ion is placed at the closest distance to the collision partner (which is

equal to the impact parameter) before the nuclear scattering event.

The center-of-mass scattering angle  is obtained from a lookup table as

a function of the reduced impact parameter

is obtained from a lookup table as

a function of the reduced impact parameter  and the reduced energy

and the reduced energy

which are defined as

which are defined as

|

(3.38) |

|

(3.39) |

Figure 3.13:

Tabulated scattering angle as a function of the scaled quantities

impact parameter and energy.

|

|

where the universal screening length  (3.14) and the transformed energy

(3.14) and the transformed energy

(3.6) are used.

The calculated ion trajectories presented in Fig. 3.11 show the change of

the flight direction of ions due to heavy ion-atom collisions (small impact parameter)

as well as the retention of the flight direction as ions travel along crystalline channels.

The atomic-scale distances between nuclear collision events produce continuously

plotted trajectories (every trajectory point corresponds to a single collision event).

Fig. 3.12 shows the simulated distribution of 100 boron atoms in crystalline

silicon which are implanted from the implantation window using the same implantation

conditions as for the visualized trajectories in Fig. 3.11.

The three-dimensional visualization of the tabulated scattering angle is presented

in Fig. 3.13 by using a bicubic spline interpolation. The table values of

the scattering angle are stored in a data file for 28 energy values and 17 impact

parameter values. The surface plot

(3.6) are used.

The calculated ion trajectories presented in Fig. 3.11 show the change of

the flight direction of ions due to heavy ion-atom collisions (small impact parameter)

as well as the retention of the flight direction as ions travel along crystalline channels.

The atomic-scale distances between nuclear collision events produce continuously

plotted trajectories (every trajectory point corresponds to a single collision event).

Fig. 3.12 shows the simulated distribution of 100 boron atoms in crystalline

silicon which are implanted from the implantation window using the same implantation

conditions as for the visualized trajectories in Fig. 3.11.

The three-dimensional visualization of the tabulated scattering angle is presented

in Fig. 3.13 by using a bicubic spline interpolation. The table values of

the scattering angle are stored in a data file for 28 energy values and 17 impact

parameter values. The surface plot

revealed

that a small impact parameter

revealed

that a small impact parameter  and a low energy

and a low energy  of the ion

produces strong nuclear scattering (

of the ion

produces strong nuclear scattering (

) for a binary

collision event while channeling of ions occurs at large impact parameters or at

high energies (

) for a binary

collision event while channeling of ions occurs at large impact parameters or at

high energies (

). The scattering angles of the ion and

of the recoil in the laboratory system are calculated from the center-of-mass

scattering angle

). The scattering angles of the ion and

of the recoil in the laboratory system are calculated from the center-of-mass

scattering angle  by (3.9) and (3.10), and the transferred

energy to the primary recoil atom of a collision cascade is obtained by

(3.11).

by (3.9) and (3.10), and the transferred

energy to the primary recoil atom of a collision cascade is obtained by

(3.11).

The electronic stopping process is calculated by using the Hobler model described

in Section 3.1.3. The only physical parameter required for this electronic stopping

model is the impact parameter which is determined in the BCA model when selecting

a collision partner. The model requires for every crystalline material a set of

four parameters  ,

,  ,

,  , and

, and  for each ion species

(Table 3.3). In contrast to MCIMPL, where there is only one set of parameters

per ion species for one target material available (since MCIMPL was originally

just designed for the implantation into silicon), the model parameters can be

independently calibrated for each ion-target combination in MCIMPL-II. Therefore,

different crystalline material segments can be used in one simulation domain.

Due to the fact that the model implies a dependence on the charge and the mass

of the atoms of the target material, the electronic stopping power is averaged

in the case of a compound material like SiGe. The contribution of each atom

species is considered according to the stoichiometry of the material.

In addition, a special treatment is applied for multiple collisions. While the

non-local part of the electronic stopping model is considered only once, the

local contribution to the electronic stopping process is calculated once for

each binary collision which is part of the multiple collision event.

for each ion species

(Table 3.3). In contrast to MCIMPL, where there is only one set of parameters

per ion species for one target material available (since MCIMPL was originally

just designed for the implantation into silicon), the model parameters can be

independently calibrated for each ion-target combination in MCIMPL-II. Therefore,

different crystalline material segments can be used in one simulation domain.

Due to the fact that the model implies a dependence on the charge and the mass

of the atoms of the target material, the electronic stopping power is averaged

in the case of a compound material like SiGe. The contribution of each atom

species is considered according to the stoichiometry of the material.

In addition, a special treatment is applied for multiple collisions. While the

non-local part of the electronic stopping model is considered only once, the

local contribution to the electronic stopping process is calculated once for

each binary collision which is part of the multiple collision event.

Table 3.3:

Empirical parameters for the electronic stopping process

in silicon.

| Ion species |

Charge |

Mass |

|

|

|

|

| Boron |

5 |

11.009 |

1.75 |

0.450 |

0.050 |

0.230 |

| Nitrogen |

7 |

14.006 |

1.6861 |

0.4364 |

0.3177 |

0.1101 |

| Oxygen |

8 |

15.994 |

1.55 |

0.099 |

3.193E-5 |

0.97 |

| Fluorine |

9 |

18.998 |

0.9 |

0.6586 |

0.08 |

0.0 |

| Silicon |

14 |

27.977 |

1.4 |

0.4 |

0.12 |

0.1 |

| Phosphorus |

15 |

30.994 |

1.2674 |

0.4212 |

0.1447 |

0.0253 |

| Germanium |

32 |

72.59 |

1.15 |

0.3 |

0.3 |

0.0 |

| Arsenic |

33 |

74.92 |

1.1316 |

0.3056 |

0.2991 |

0.0243 |

| Indium |

49 |

114.82 |

1.1 |

0.3 |

0.5 |

0.0 |

| Antimony |

51 |

120.9 |

1.1 |

0.3 |

0.5 |

0.0 |

| Xenon |

54 |

131.3 |

1.1 |

0.3 |

0.5 |

0.0 |

|

The calculation of implantation induced point defects in crystalline materials is

performed with the computationally efficient modified Kinchin-Pease damage model

in combination with the Hobler recombination model as described in

Section 3.1.4. The ion species dependent parameters of the empirical

recombination model (Table 3.4) are stored in common with the parameters of

the electronic stopping model in an ASCII data file. This file contains one data

record for each combination of ion species and target material which holds all

empirical parameters including the atomic number and atomic mass of the ion species.

Table 3.4:

Recombination model parameters for different dopant

species in silicon.

| Ion species |

|

(cm (cm ) ) |

| Boron |

0.139 |

|

| Phosphorus |

1.0 |

|

| Arsenic |

2.1 |

|

|

Figure 3.14:

Illustration of the dose dependence for boron profiles using

an energy of 20keV and a tilt of 0 , simulated with the Kinchin-Pease model.

, simulated with the Kinchin-Pease model.

|

|

Fig. 3.14 compares simulated boron profiles for 20keV channeling implantations

in (100) silicon (shown by continuous lines) to SIMS measurements for the doses of

,

,  , and

, and  cm

cm . The one-dimensional profiles were

obtained with one million simulated particles using an ion beam divergence of

. The one-dimensional profiles were

obtained with one million simulated particles using an ion beam divergence of

in the simulations. It can be observed that the shape of the

boron profiles is significantly influenced by the produced crystal damage.

The accumulation of point defects with increasing implantation dose is well

reproduced by the combined damage modeling approach based on the generation and

recombination of point defects. It should be noted that the assumption of a native

oxide film of 1nm thickness on the wafer surface is necessary to obtain a good

agreement between boron simulation results and experimental data.

in the simulations. It can be observed that the shape of the

boron profiles is significantly influenced by the produced crystal damage.

The accumulation of point defects with increasing implantation dose is well

reproduced by the combined damage modeling approach based on the generation and

recombination of point defects. It should be noted that the assumption of a native

oxide film of 1nm thickness on the wafer surface is necessary to obtain a good

agreement between boron simulation results and experimental data.

The atomic-scale simulation of ion implantation processes using a Monte Carlo

method is one of the most time-consuming computational tasks in semiconductor

process simulation. On the one hand side, dramatically shrinked geometries of

advanced devices require highly accurate simulation results by computing a

very large number of ion trajectories and, on the other hand side, applications

with higher implantation energies produce long trajectories in large-volume

simulation domains. Three speed-up methods can be employed for the trajectory

calculation in three-dimensional applications to get shorter

simulation runtimes without loosing accuracy:

- Trajectory-Split method

- Trajectory-Reuse method

- Parallelization of trajectory calculation

The simulation of ion implantation produces a statistical distribution of the

implanted dopant ions (in initial ion direction and lateral), where most of the

simulated ions come to rest at a penetration depth close to the projected range

in the target. For instance, regions with a dopant concentration of three orders

of magnitudes smaller than the maximum concentration are reached just by one

of thousand implanted ions. The statistical accuracy of simulation results

becomes even worse in regions with lower dopant concentrations, since a

reasonable simulation result includes three to five orders of the dopant

concentration. At least some implanted particles have to be counted even in

histogram cells located in peripheral regions with a very low concentration

level of dopants, since no significant information can be derived from a

histogram cell which contains only one implanted particle.

The basic idea of the Trajectory-Split method is to increase the number of ion

trajectories that end up in regions with a bad statistical representation of

dopants by splitting a particle trajectory [80,42].

The splitting of a particle produces several particles with the same physical

properties as the original particle but with a reduced weighting factor.

The increase in the number of dopants, vacancies, and interstitials caused by

a splitted particle are multiplied with the weighting factor before they are

stored in the corresponding histogram. While the simulation of a molecular ion

is performed with a weighting factor larger than one to account for statistical

identical particles of the same atom species in the molecule [81],

the weighting factor has to be below one for a splitted elemental ion to

conserve the total implantation dose. The build-up of a trajectory tree is

implemented by the full calculation of a primary trajectory and determining

of the split points along this trajectory according to various rules.

Afterwards a new trajectory is calculated from every split point up to the

end point. In crystalline materials the vibration of the lattice atoms

guarantees that two branches of a trajectory tree are not identical after

a split point despite equal initial conditions at the split point.

Figure 3.15:

Monte Carlo simulation of a boron trajectory tree

with a split depth value of 5, an energy of 10keV, and a tilt of 0 in crystalline silicon.

in crystalline silicon.

|

|

The effect of the Trajectory-Split method is that one implanted particle

delivers several effective ions which share the same initial part of the

trajectory. Therefore less initial ions are required to get a simulation

result with the same statistical accuracy. The sharing of parts of a trajectory

reduces the average calculation time for trajectories of effective ions.

The visualized boron trajectory tree, shown in Fig. 3.15, has a split depth

of five, which corresponds to  trajectories with a particle weight of

trajectories with a particle weight of

. Finally, it should be noted that the Trajectory-Split method is

typically applied for crystalline materials to reduce long computation times

and to improve the statistical accuracy of doping profiles in the channeling

tail region.

. Finally, it should be noted that the Trajectory-Split method is

typically applied for crystalline materials to reduce long computation times

and to improve the statistical accuracy of doping profiles in the channeling

tail region.

The basic idea of the Trajectory-Reuse method is to use the fact that different

regions of the simulation domain behave identical with respect to the trajectory

calculation [42].

Therefore it is possible to calculate a trajectory only once and to copy it

to other regions. The copying of trajectories can be interpreted as spreading

one-dimensional simulation results over a two- or three-dimensional simulation

domain as far as possible. In terms of trajectory calculation two regions

are considered identical, if all material properties that influence the particle

motion are equal along the complete trajectory. In the case of amorphous

materials only the density and composition of the material are considered in

the simulation, while in the case of crystalline materials the trajectory is

also influenced by the damage distribution in the material.

Therefore the Trajectory-Reuse method can only be applied to amorphous

materials, because regions with an exactly identical damage distribution

along the complete trajectory are very improbable. They exist only for an

initially undamaged crystal structure.

Figure 3.16:

Illustration of the Trajectory-Reuse method for

two different materials.

|

|

Fig. 3.16 demonstrates how the Trajectory-Reuse method works for a

trench structure and for crossing the boundary between two amorphous materials

A and B. As described in Section 3.2.2 the implantation window is subdivided into

subwindows and one ion is started from each subwindow during every time step.

The Trajectory-Reuse algorithm splits a calculated trajectory which goes through

different materials into several sub-trajectories, one for each amorphous

material, and stores the obtained sub-trajectories in a list. All parts of a

calculated trajectory in crystalline materials are neglected. When the next

ion is started, the algorithm searches through the stored trajectory list.

The target material of a stored trajectory must be identical to the entrance

material of the ion and the ion energy must be less than the energy loss

along a stored trajectory. A new trajectory is calculated and

added to the trajectory list, if no suitable trajectory is available in the

list.

along a stored trajectory. A new trajectory is calculated and

added to the trajectory list, if no suitable trajectory is available in the

list.

The Trajectory-Reuse method improves significantly the simulation speed for

three-dimensional implantation applications, since large regions of MOS

transistor structures are typically composed of amorphous materials.

Finally, it should be noted that the performance gain of this method increases

with decreasing subwindow size.

The three-dimensional Monte Carlo simulation of ion implantation requires fairly

long simulation run-times to achieve accurate simulation results in complex target

structures, which can be in the order of several days on a modern computing environment.

The simulation performance can be significantly improved by parallelization of the

trajectory calculation. Two parallelization strategies can be used in principle

for the trajectory calculation:

- Parallel computing on a cluster of workstations

- Parallel computing on a shared-memory multiprocessor system

A parallelization method based on the Message Passing Interface (MPI) was

implemented in MCIMPL [82]. The intention was to perform a

distributed simulation on a cluster of workstations which are connected over a

slow network. The simulation domain was geometrically distributed among several

workstations which have to exchange only a small amount of data during the

simulation. Due to the distribution of the memory requirement among several

workstations, small workstations could be used for three-dimensional simulations.

However, the current status of the object-oriented simulator MCIMPL-II is that

the trajectory calculation is implemented only in a sequential manner.

For future work, a powerful parallelization of the simulator can be achieved

by using OpenMP based parallel computing on a shared-memory multiprocessor

architecture [83].

The OpenMP standard provides a portable standard parallel API specifically for

programming shared-memory multiprocessor systems. This standard supports also

an incremental parallelization by adding compiler directives to the

source code. The execution of the simulation program on one multiprocessor

workstation ensures a more reliable operation for longer simulation runs

compared to a network based MPI solution. The damage accumulation during the

simulation has to be considered for parallel computing of trajectories. Only a

small error occurs, if the trajectories for all subwindows of the implantation

window are computed in parallel using the initial damage distribution of the

current time step. At the end of the time step, it has to be ensured that the

newly generated damage is updated in the shared internal data structures before

proceeding with the next time step.

After the calculation of the desired number of ion trajectories, the doping

information is stored in histogram cells aligned on an orthogonal grid. Each

histogram cell contains a certain number of implanted ions, and the doping

concentration within a cell is given by the number of ions divided by the

volume of the cell. The statistical nature of the Monte Carlo implantation

process produces a statistical fluctuation in the obtained raw cellular doping

information. In particular, three-dimensional Monte Carlo implantation results

have inherently large variances in the peripheral regions.

An advanced smoothing technique based on a Bernstein polynomial approximation

has been developed [84,85,86,14]

in order to transfer the cellular data to an unstructured destination grid

which is suitable for the subsequent process simulation step. Finite element

simulations are used in the next simulation step to imitate thermal annealing

processes which are required to activate the dopants and to eliminate the

substrate damage. On the one hand side, the postprocessing procedure performs

the necessary interpolation operation, and on the other hand side, it reduces

the statistical noise of the obtained doping and damage data.

Figure 3.17: